What Is Control Chart

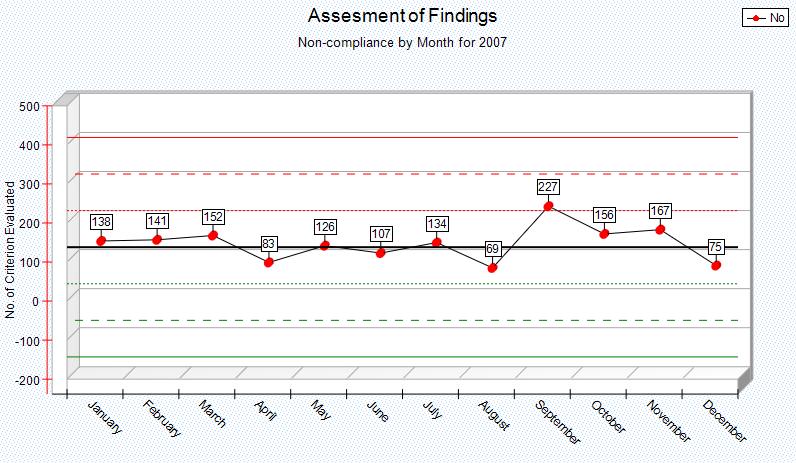

It is more appropriate to say that the control charts are the graphical device for statistical process monitoring spm.

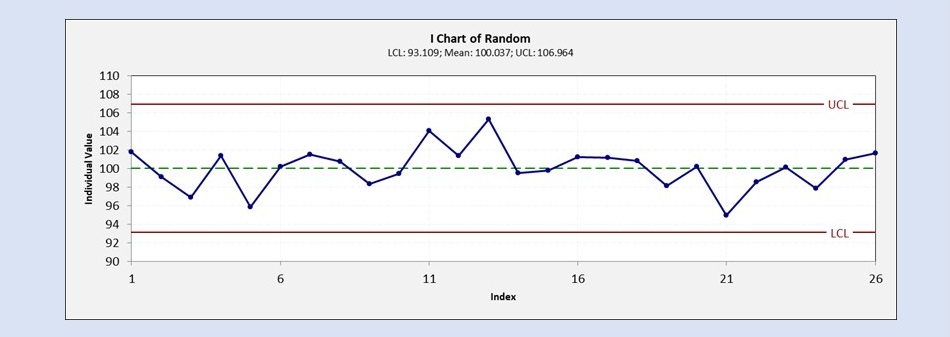

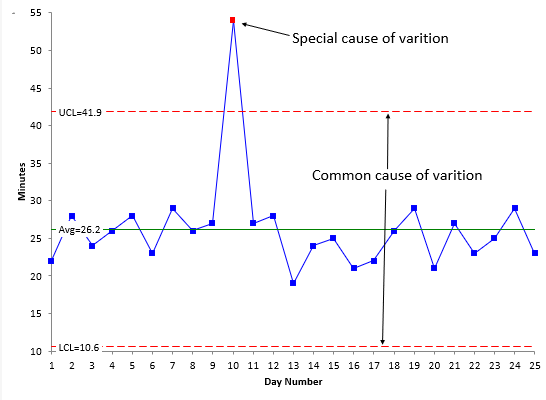

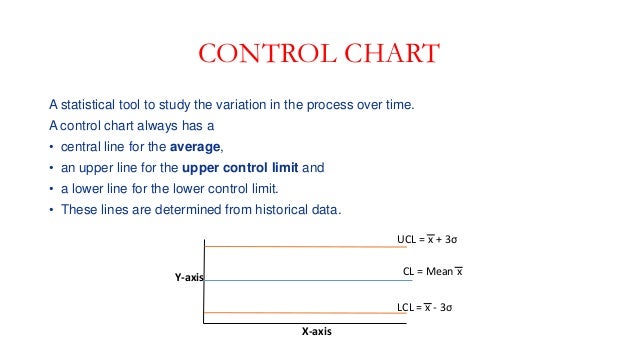

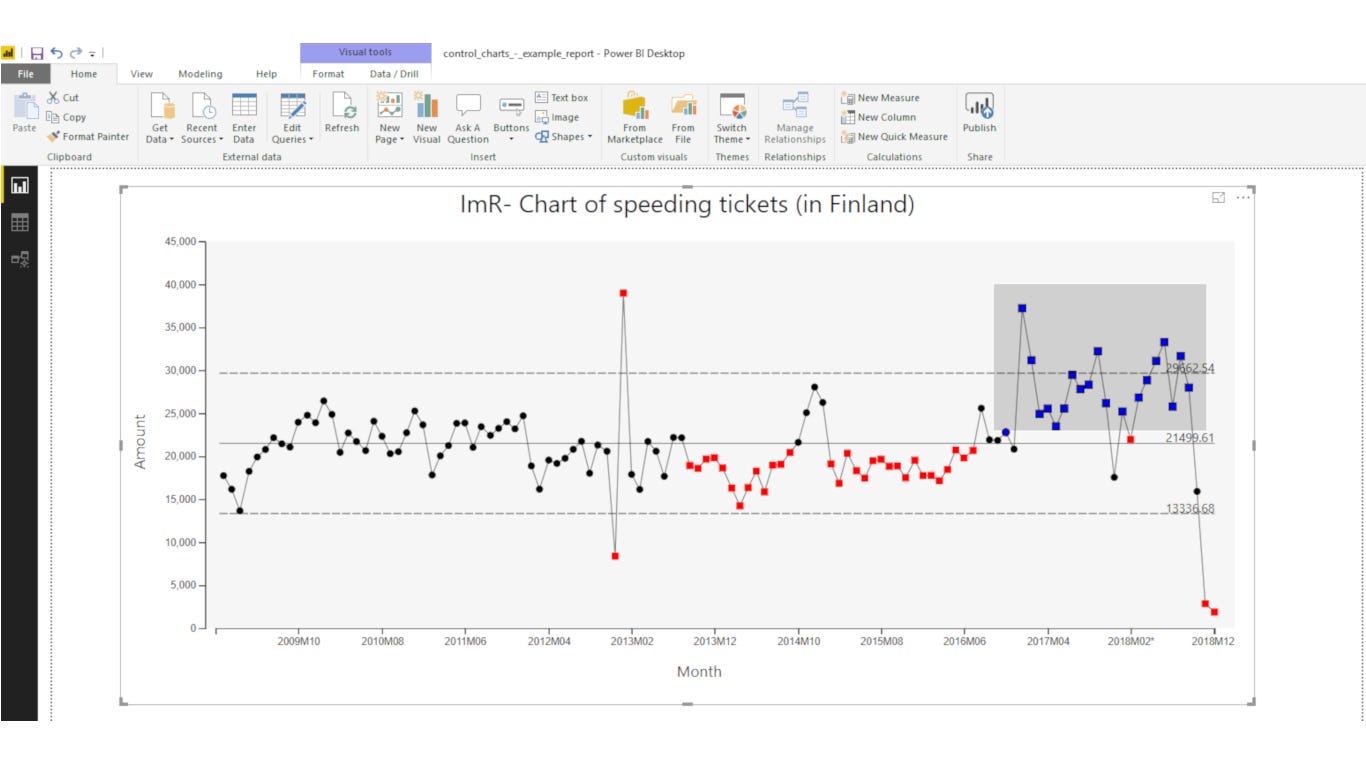

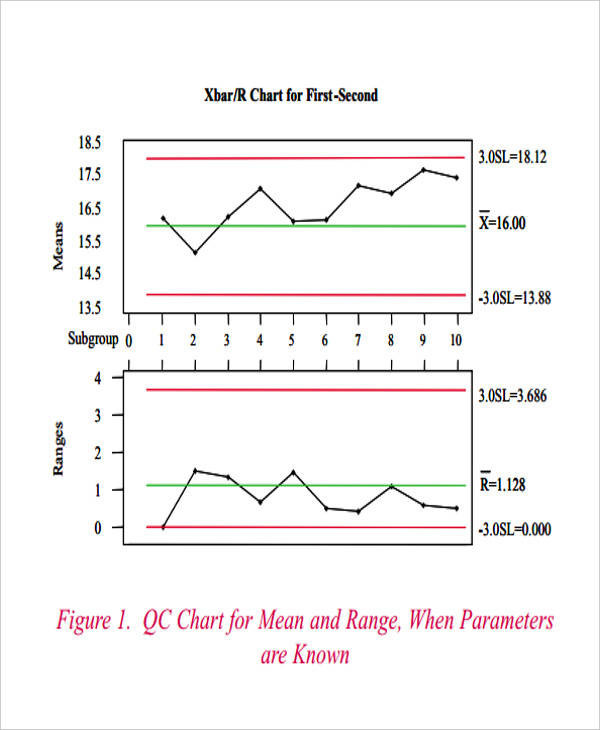

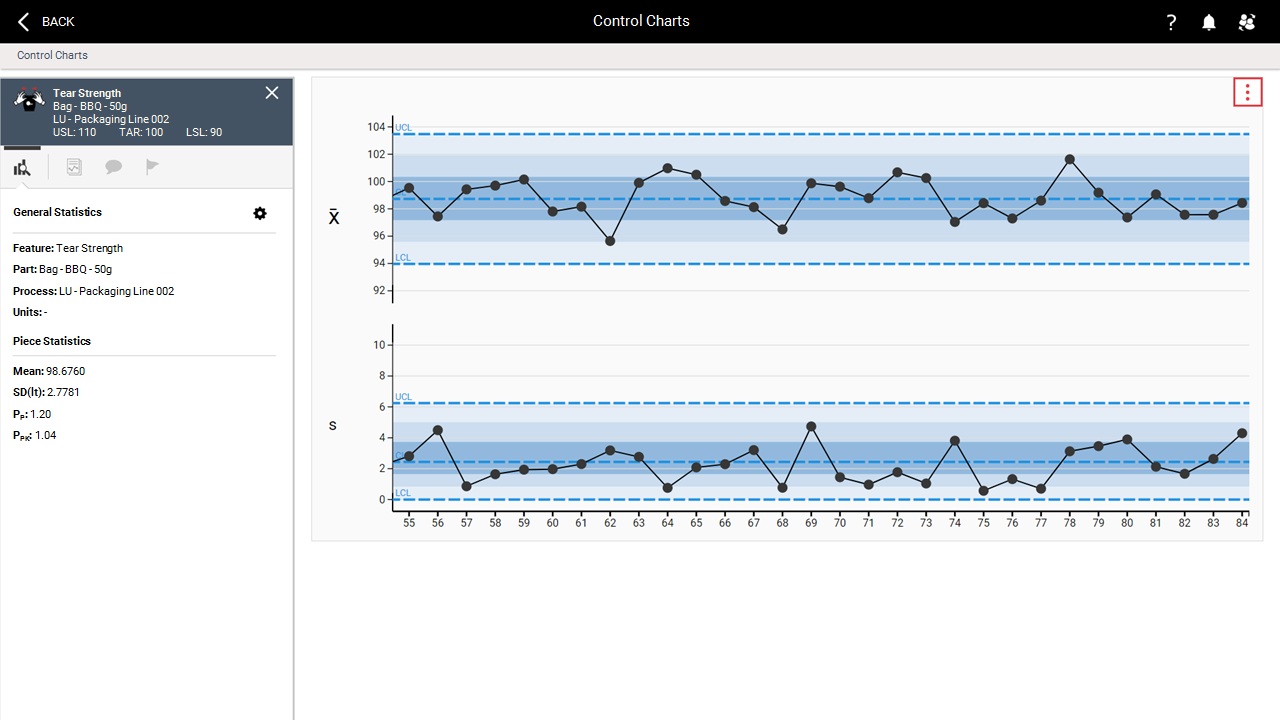

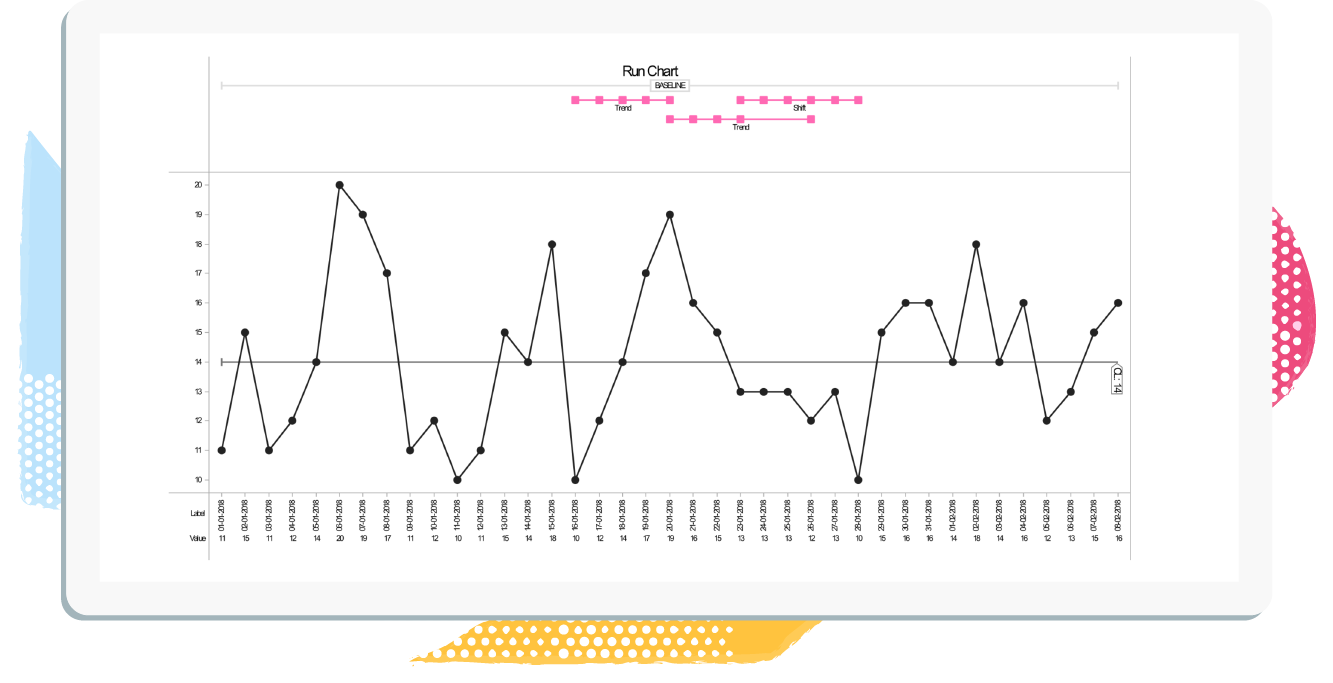

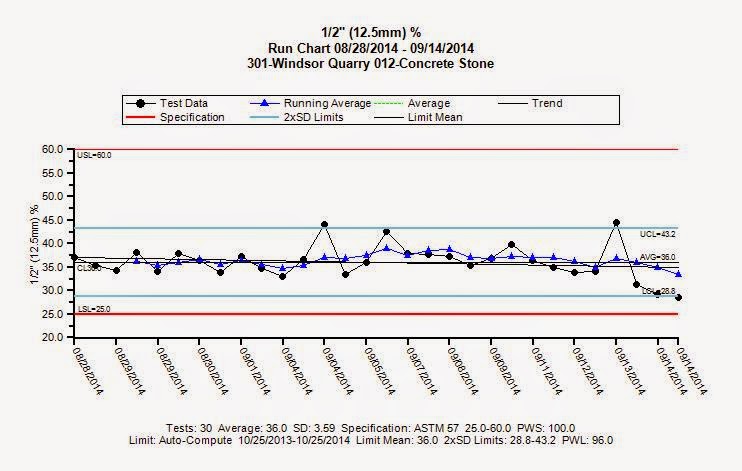

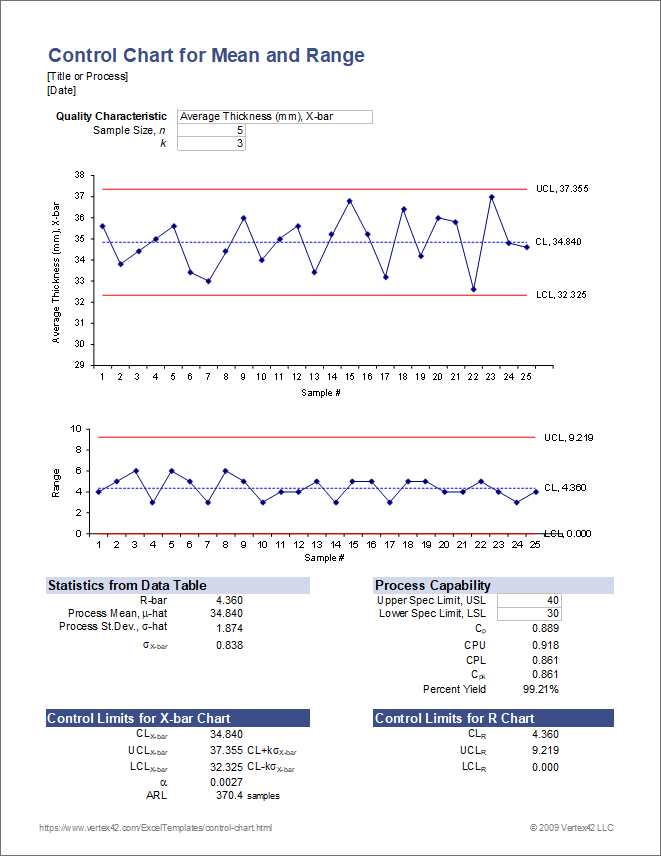

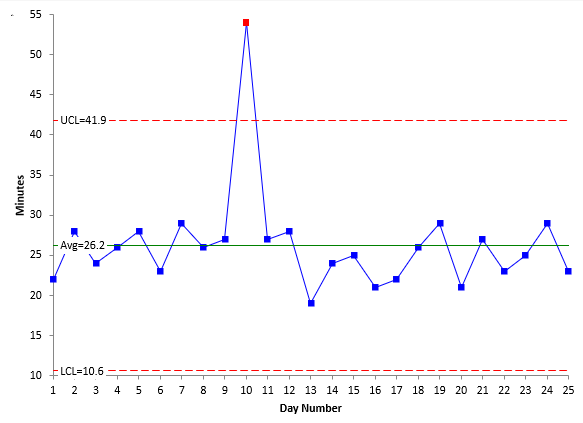

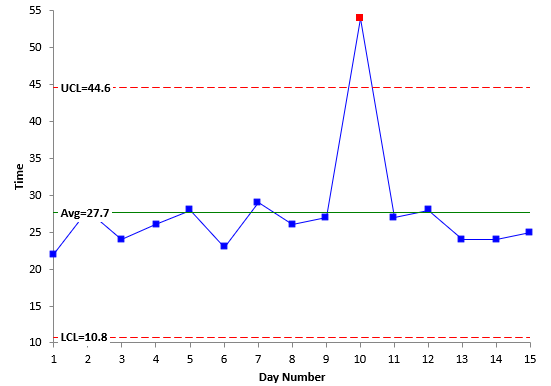

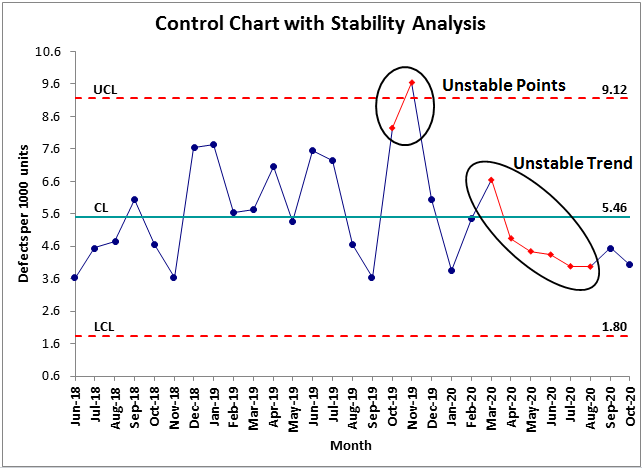

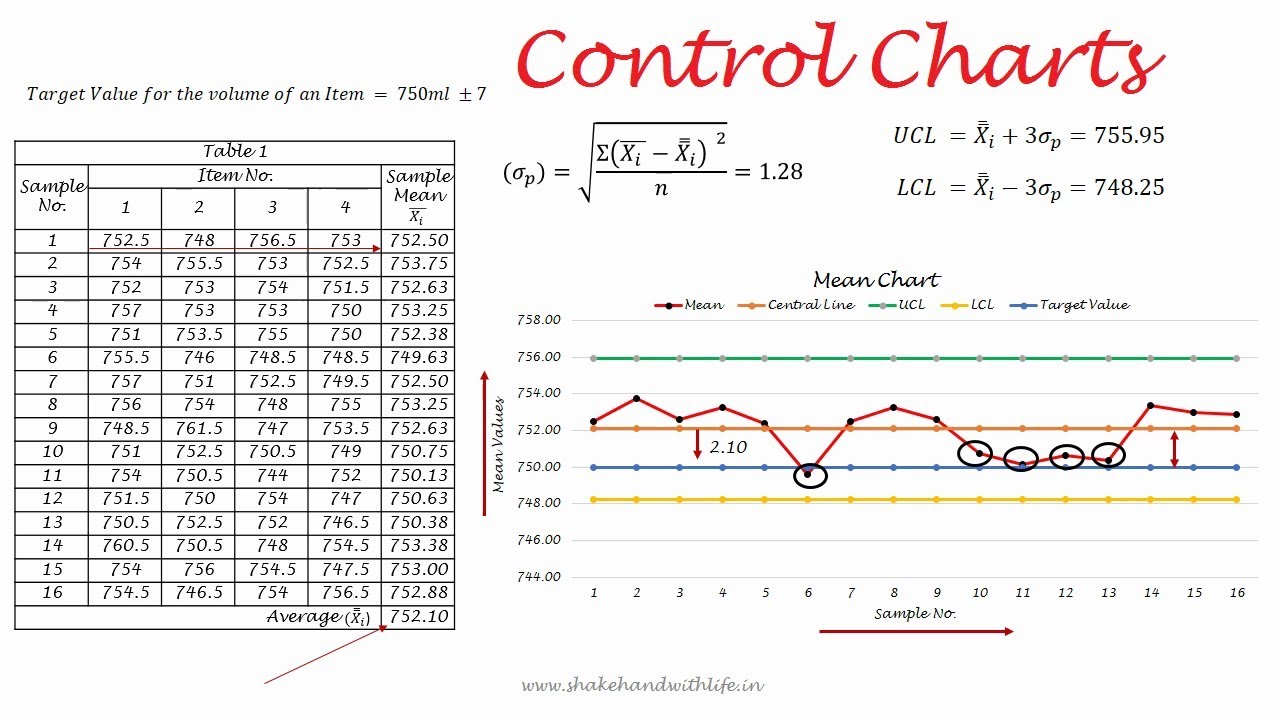

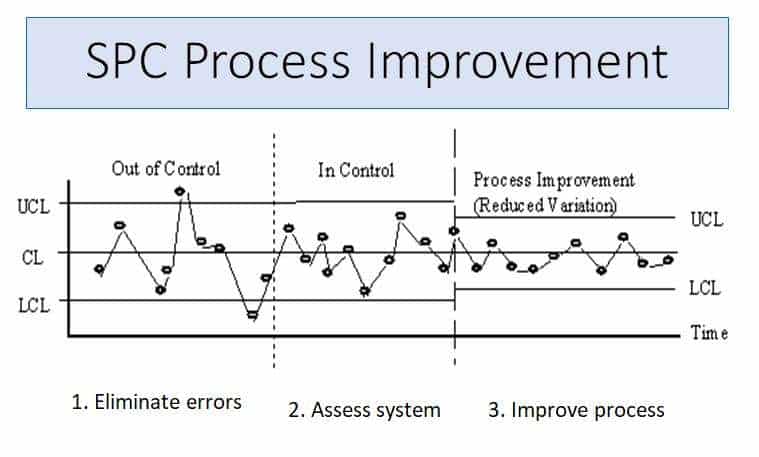

What is control chart. Statistical tool used in quality control to 1 analyze and understand process variables 2 determine process capabilities and to 3 monitor effects of the variables on the difference between target and actual performance. A less common although some might argue more powerful use of control charts is as an analysis tool. A control chart tells you if your process is in statistical control.

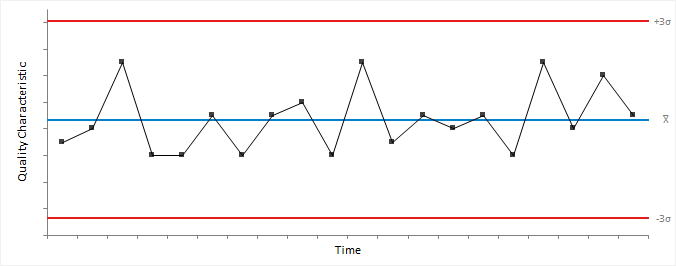

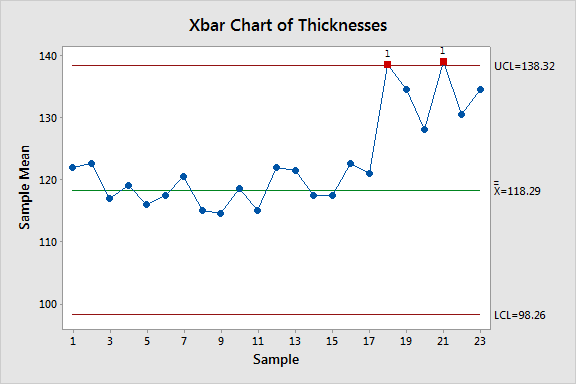

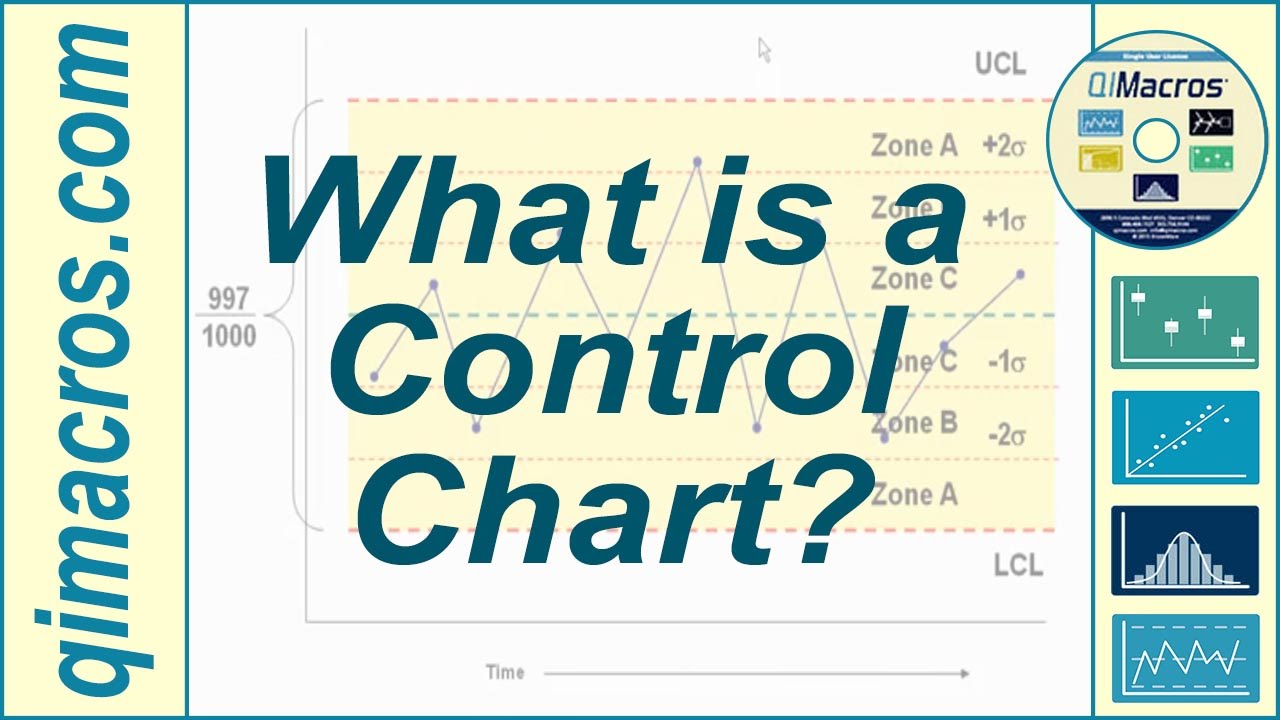

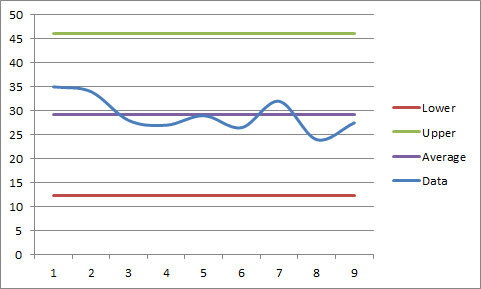

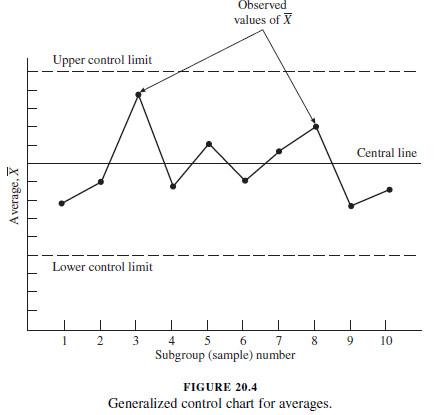

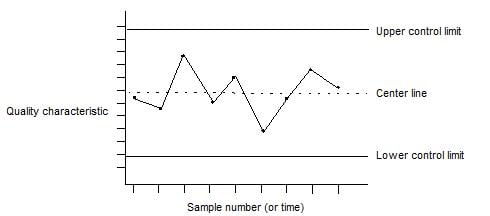

Control charts also known as shewhart charts after walter a. This pattern is typical of processes that are stable. The control chart is a graph used to study how a process changes over time.

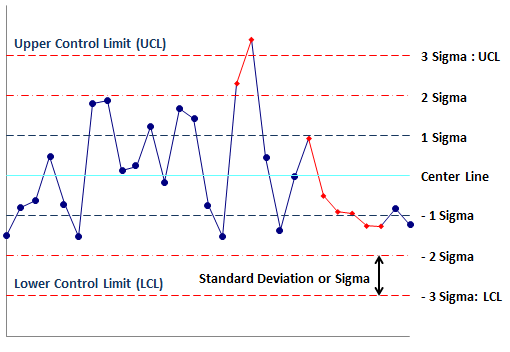

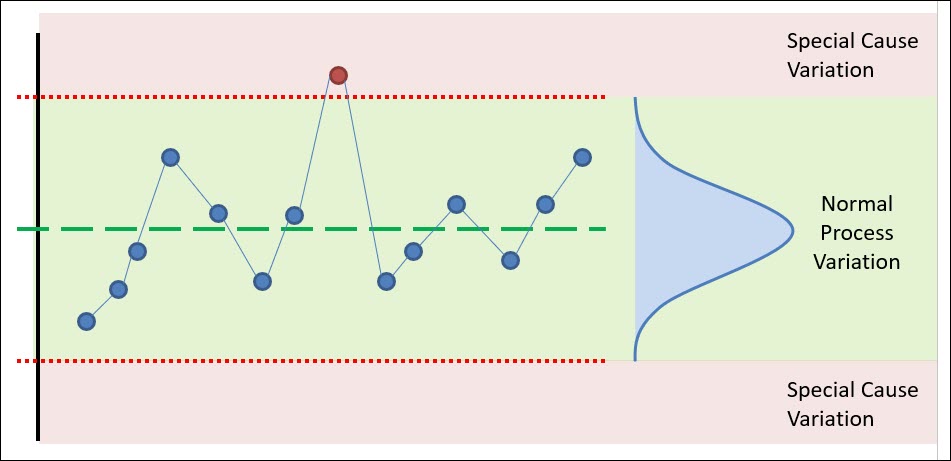

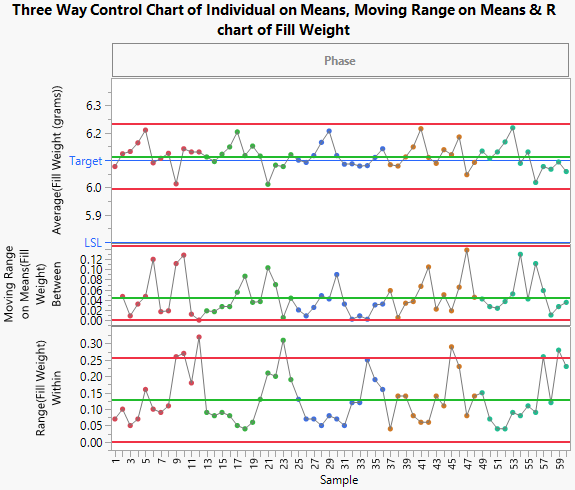

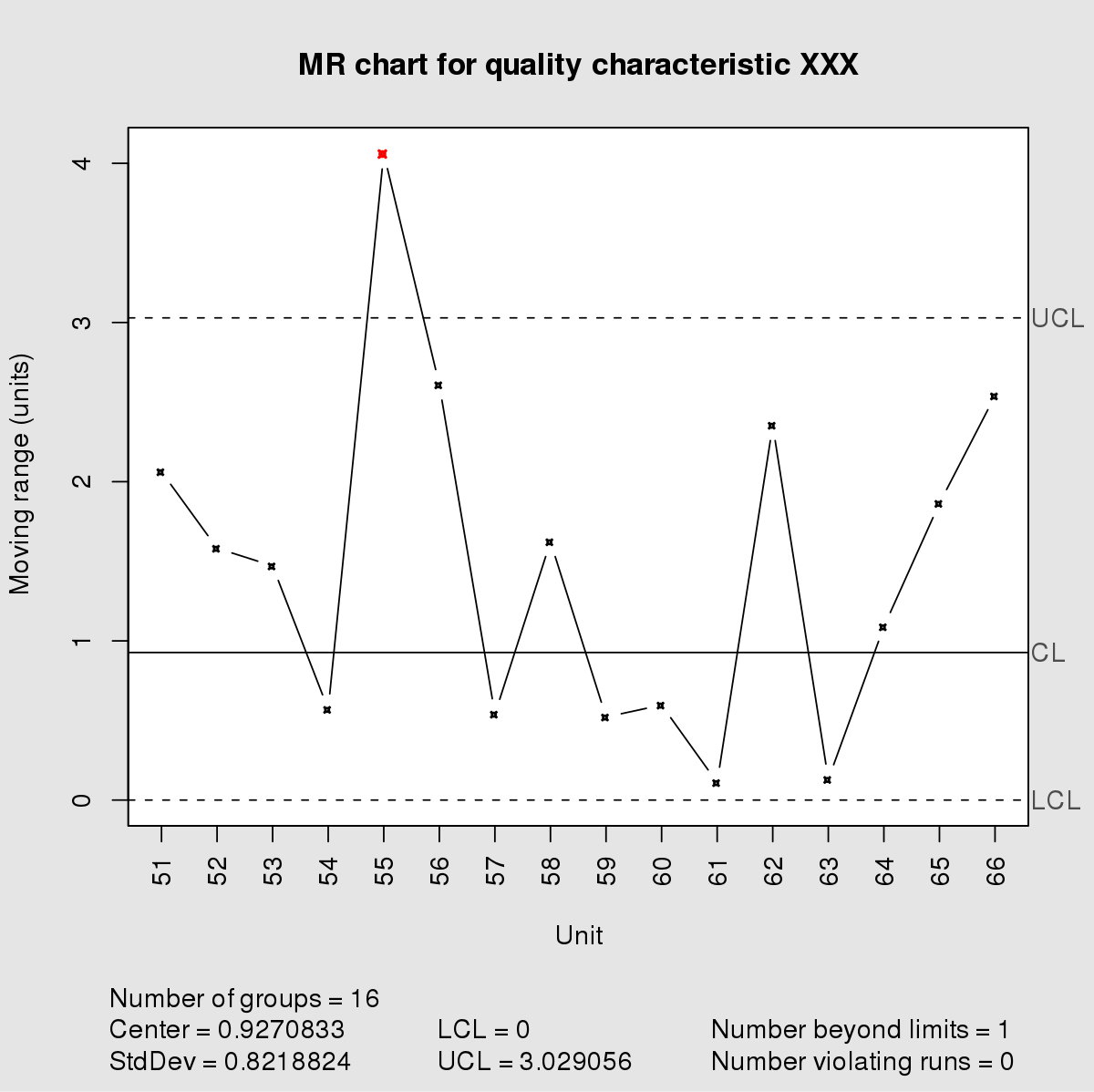

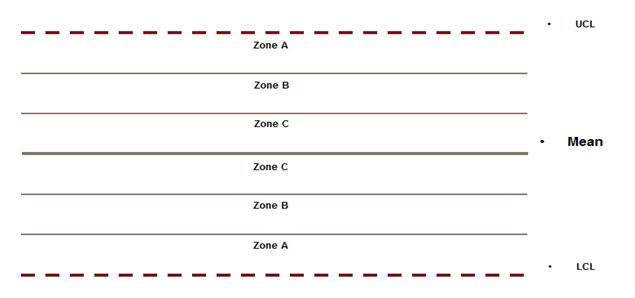

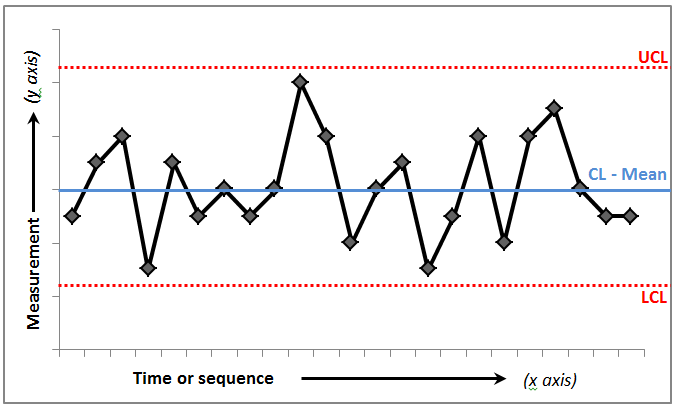

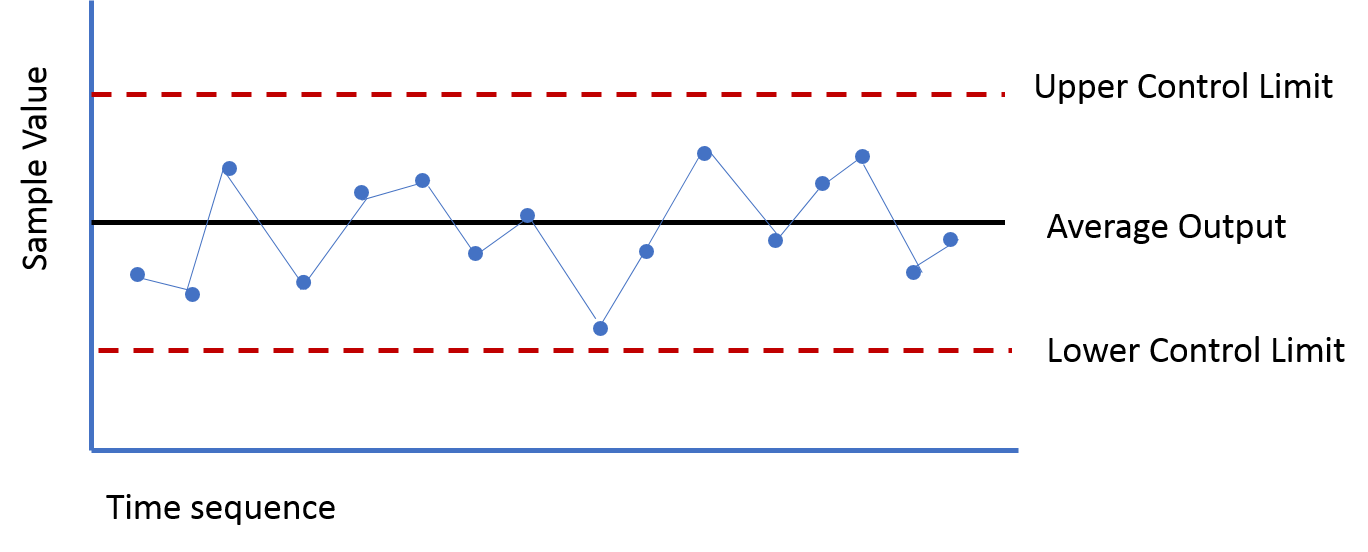

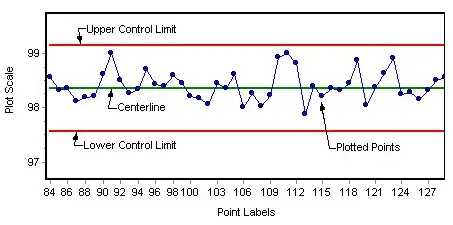

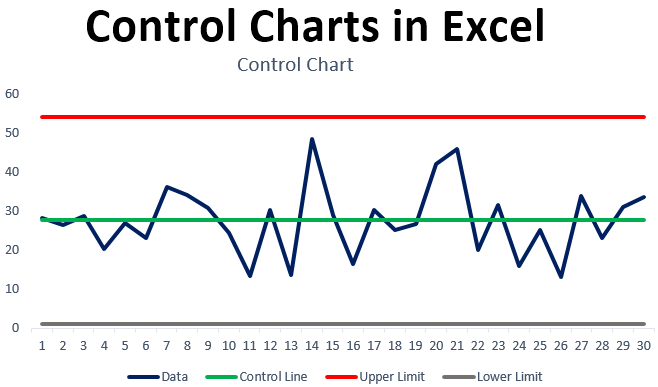

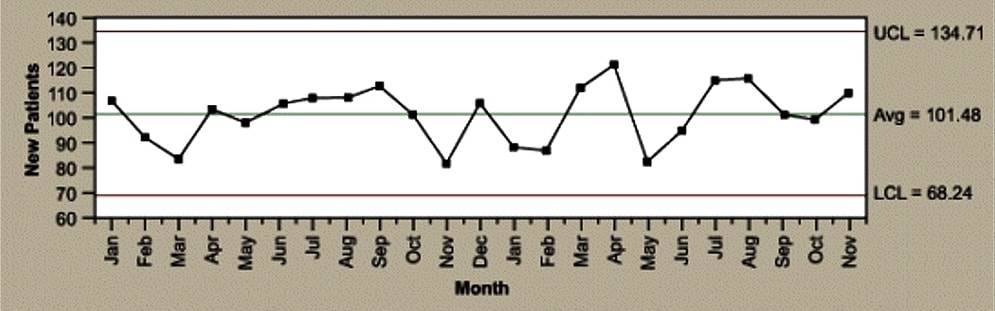

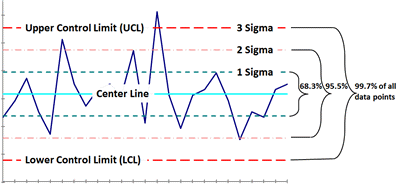

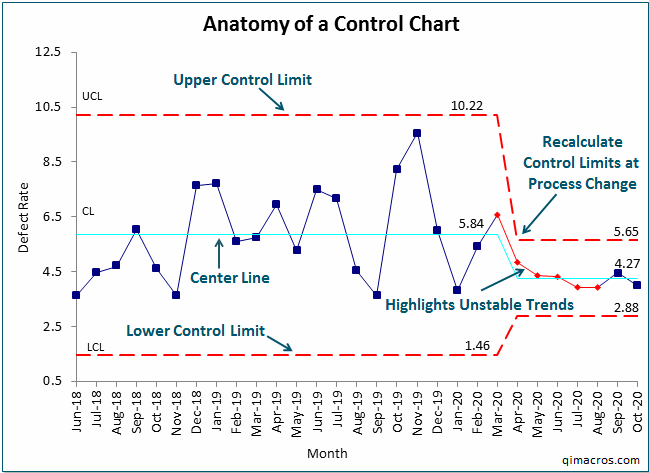

The report will fit on either a4 or letter sized pages in both portrait and landscape modes note there is a known issue printing in landscape using chrome. Data are plotted in time order. A control chart always has a central line for the average an upper line for the upper control limit and a lower line for the lower control limit.

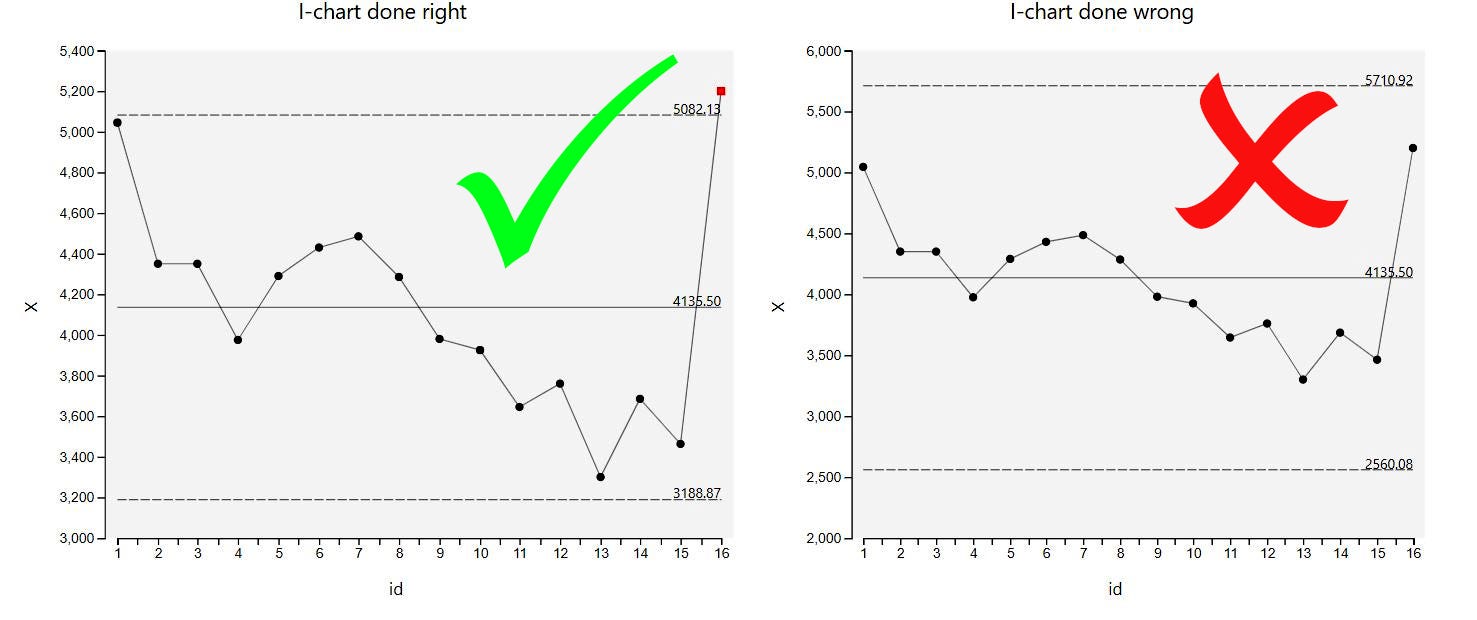

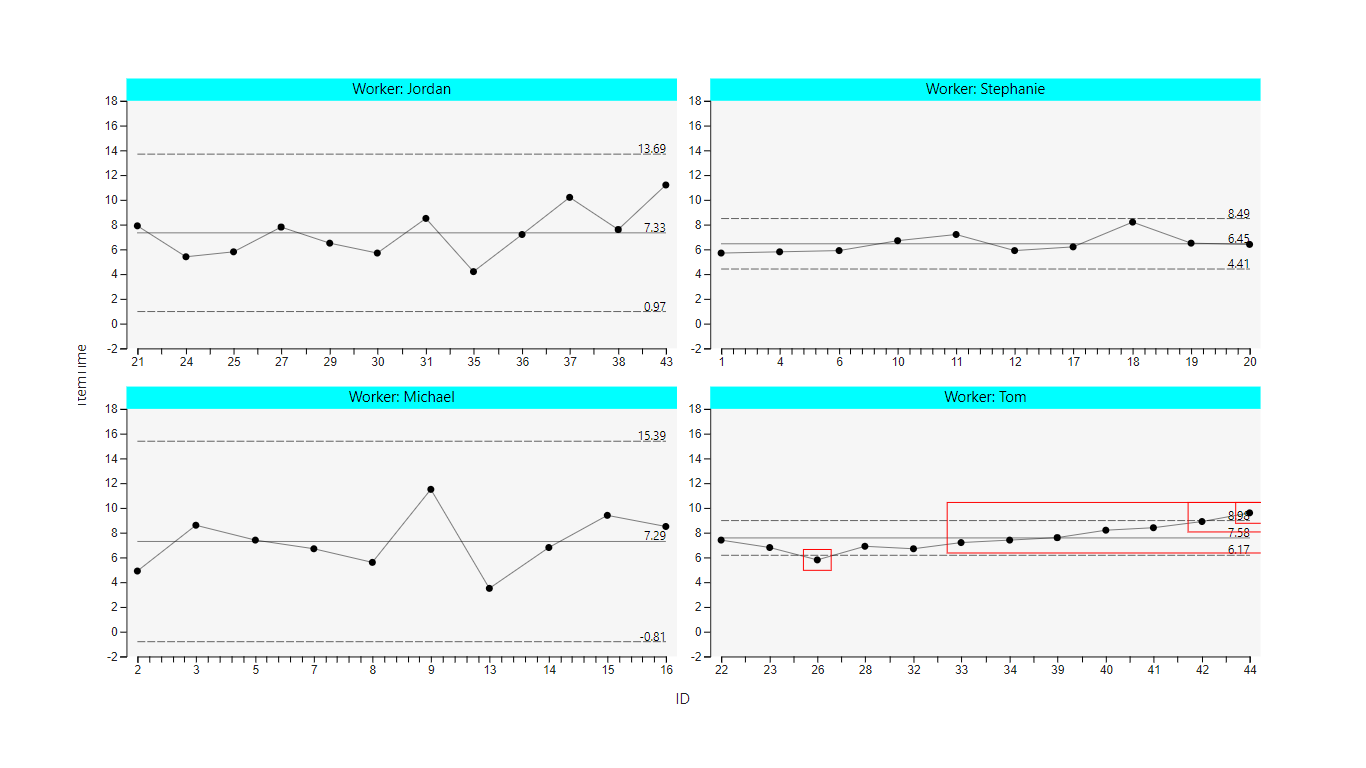

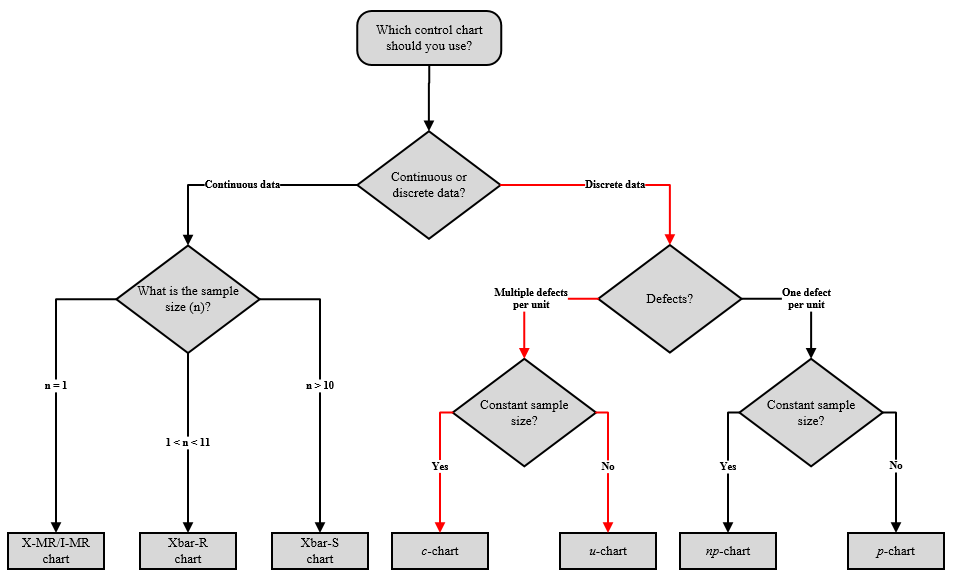

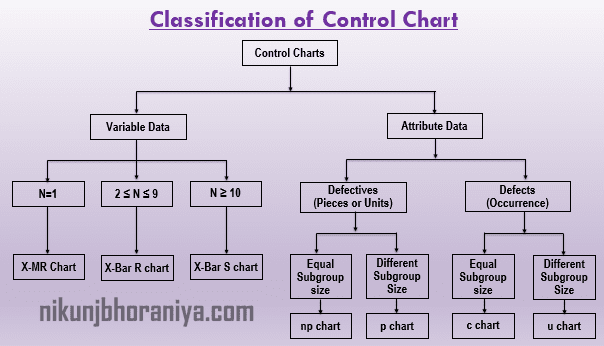

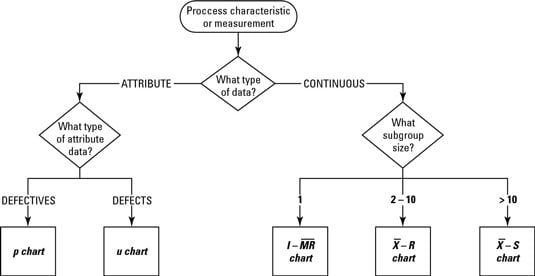

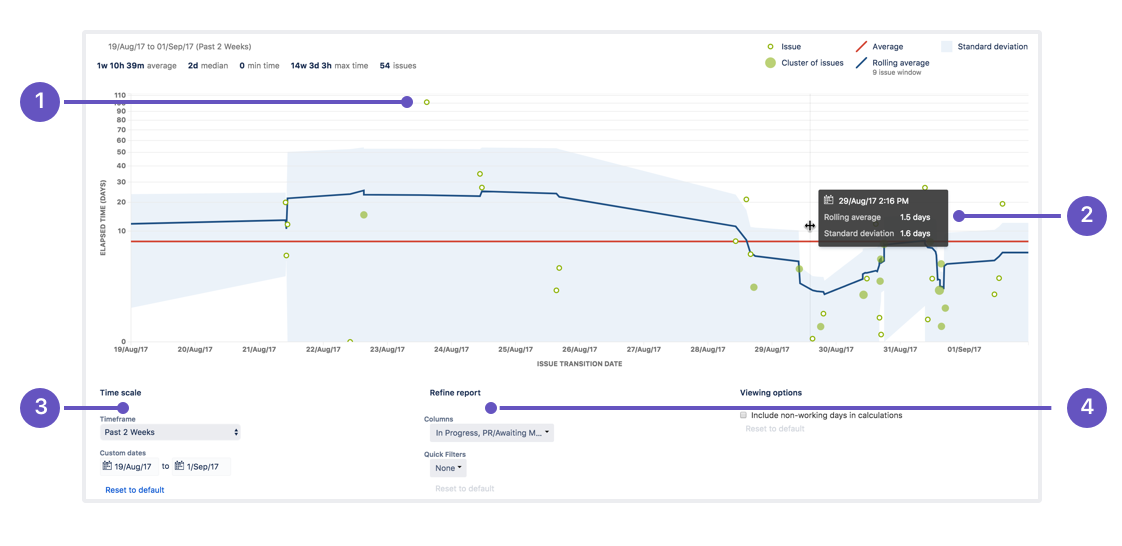

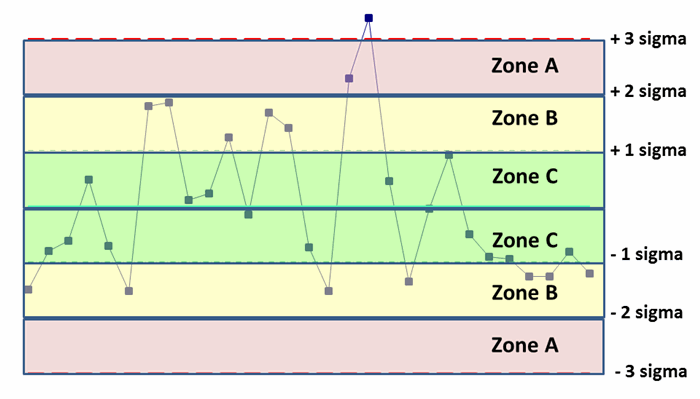

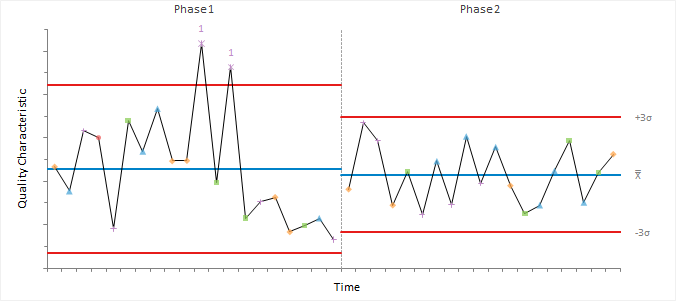

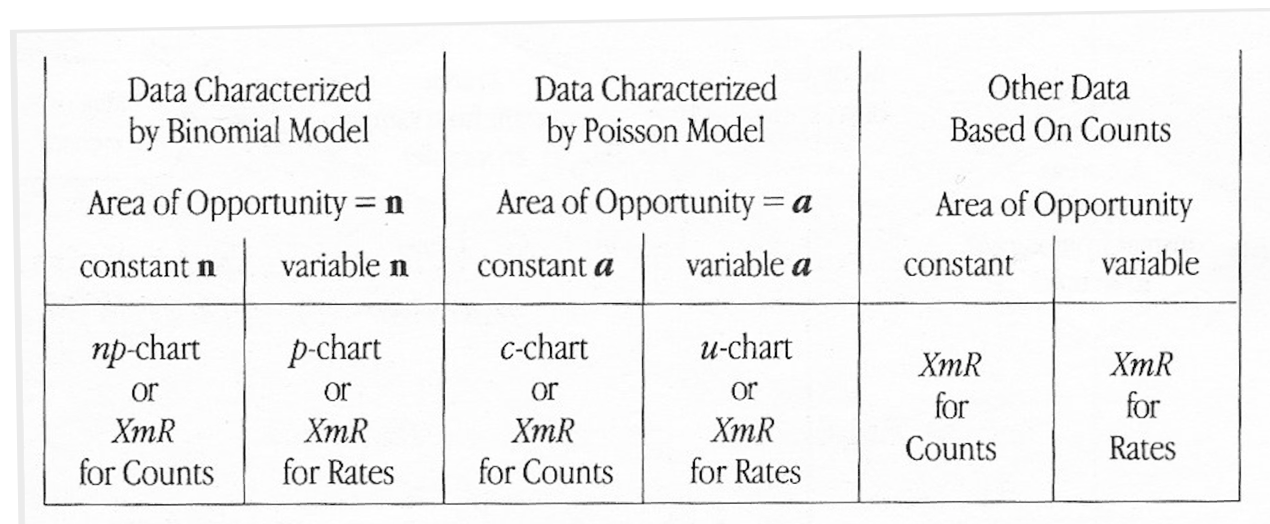

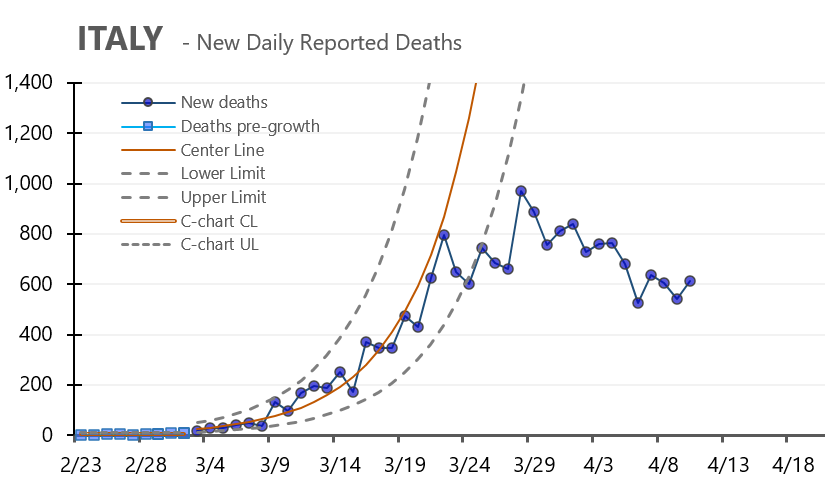

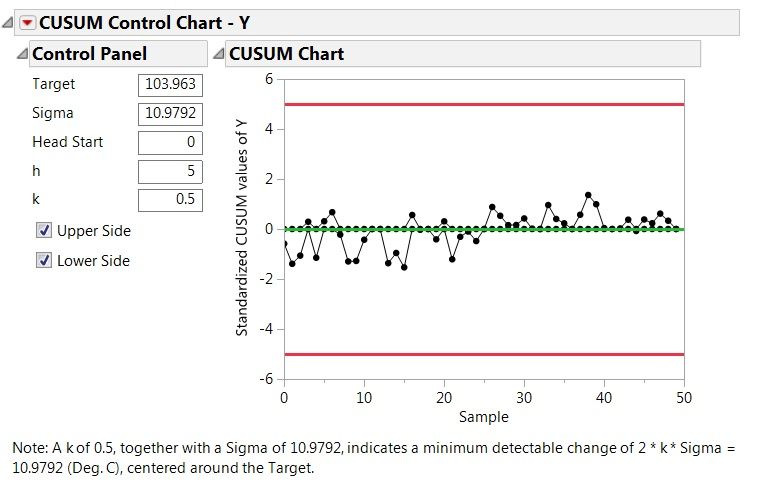

The descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation followed by a description of the method for using control charts for analysis. These lines are determined from historical data. To print the report view the report and use the print functionality for your browser.

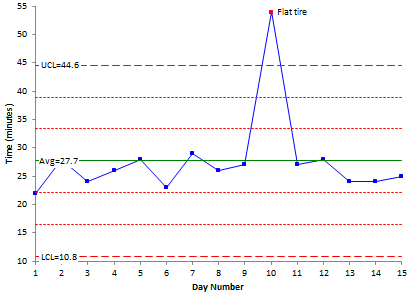

Also they have many simple applications such as professors using them to evaluate tests scores. They can be used in manufacturing to test if machinery are producing products within specifications. A control chart is a method for measuring change.

Control charts have two general uses in an improvement project. Printing the control chart. The first referred to as a univariate control chart is a graphical display chart of.

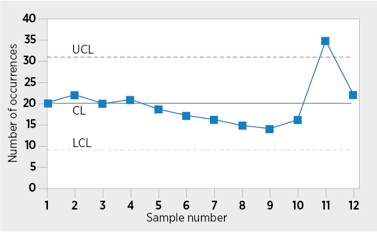

Three characteristics of a process that is in control are. Control charts indicate upper and lower control limits and often include a central average line to help detect trend of plotted values. A control chart is used to monitor a process variable over time.

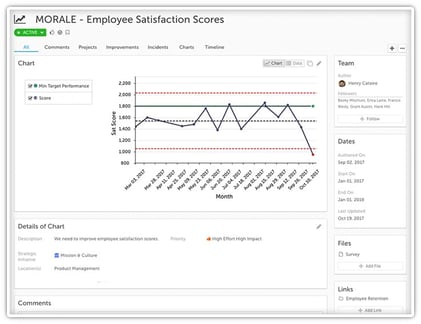

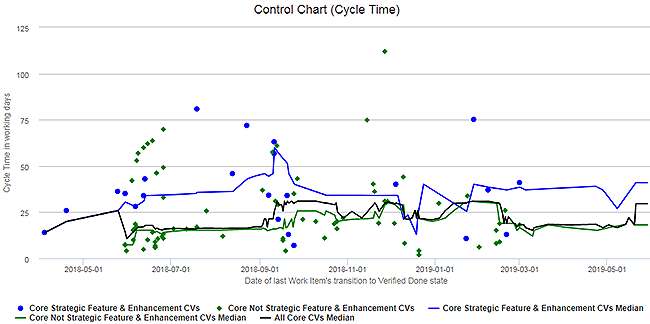

If you have information about your business that you want to measure and analyze such as manufacturing defects patient wait times or how long customers take to pay the control chart can map out the data over time. On the number of process characteristics to be monitored there are two basic types of control charts. It provides a picture of the process variable over time and tells you the type of variation you are dealing with as you move forward with continuous improvement.

Control charts are used to routinely monitor quality. Control charts have many uses. Control charts are an efficient way of analyzing performance data to evaluate a process.

Shewhart or process behavior charts are a statistical process control tool used to determine if a manufacturing or business process is in a state of control. The most common application is as a tool to monitor process stability and control.

/spc-lesson-3-screenshotC7BF01ABD937750608D37545.jpg?sfvrsn=2)