End Mill Rpm Chart

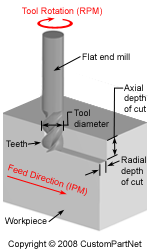

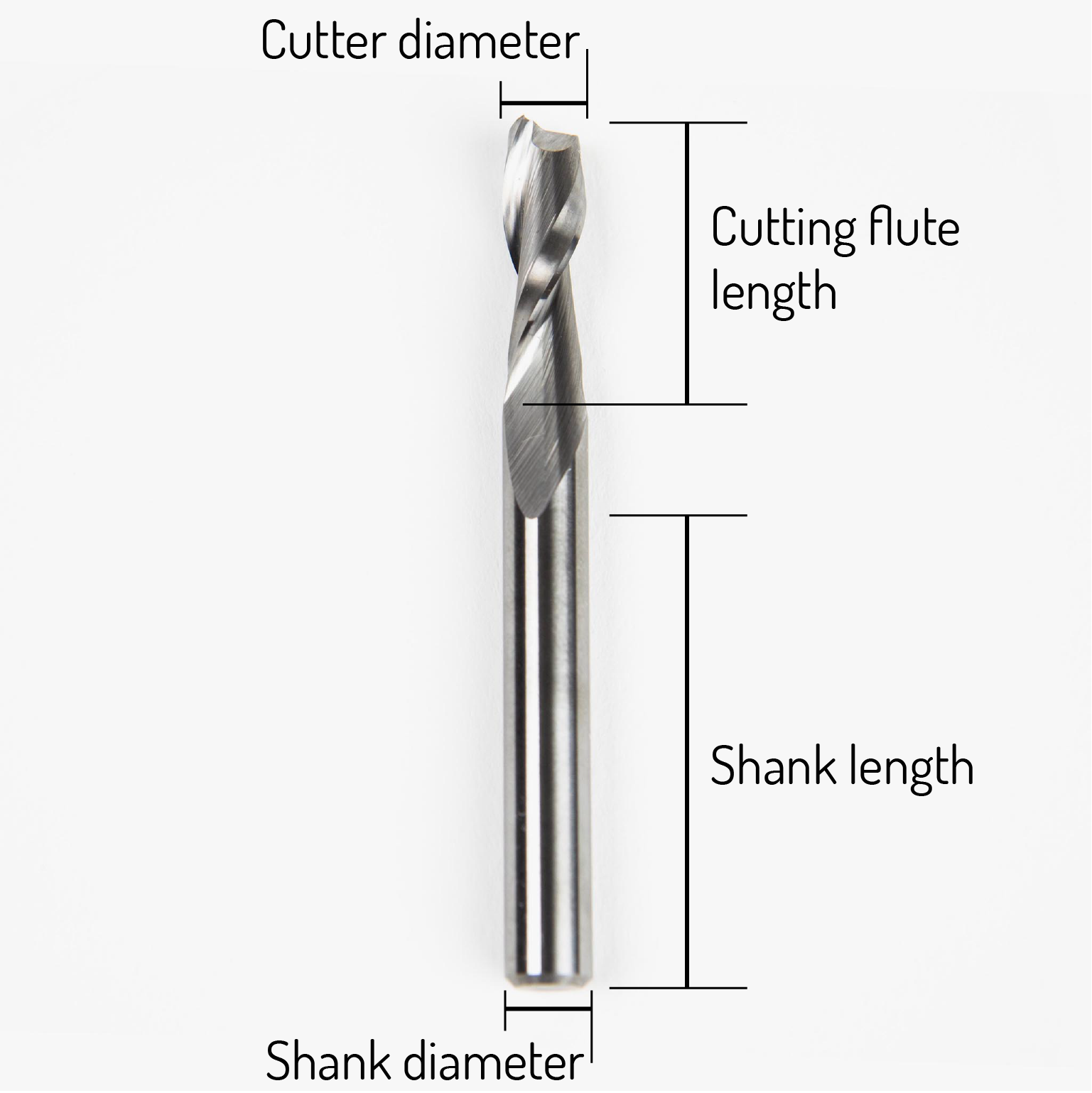

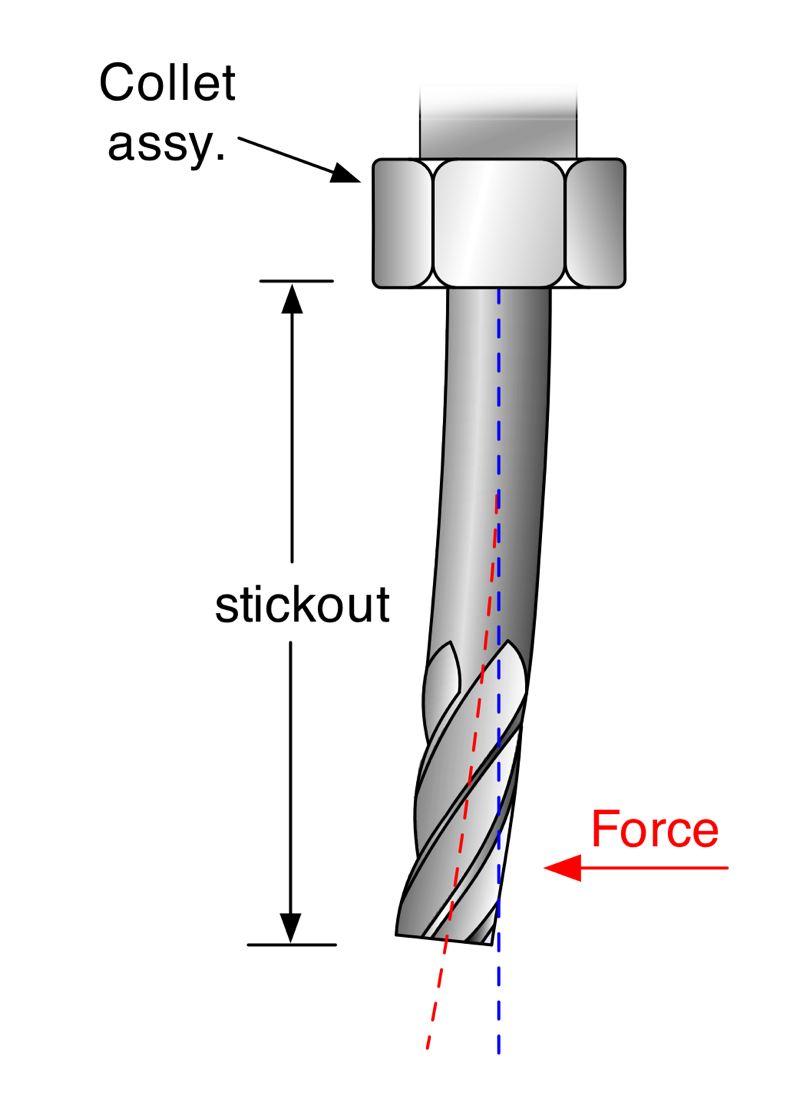

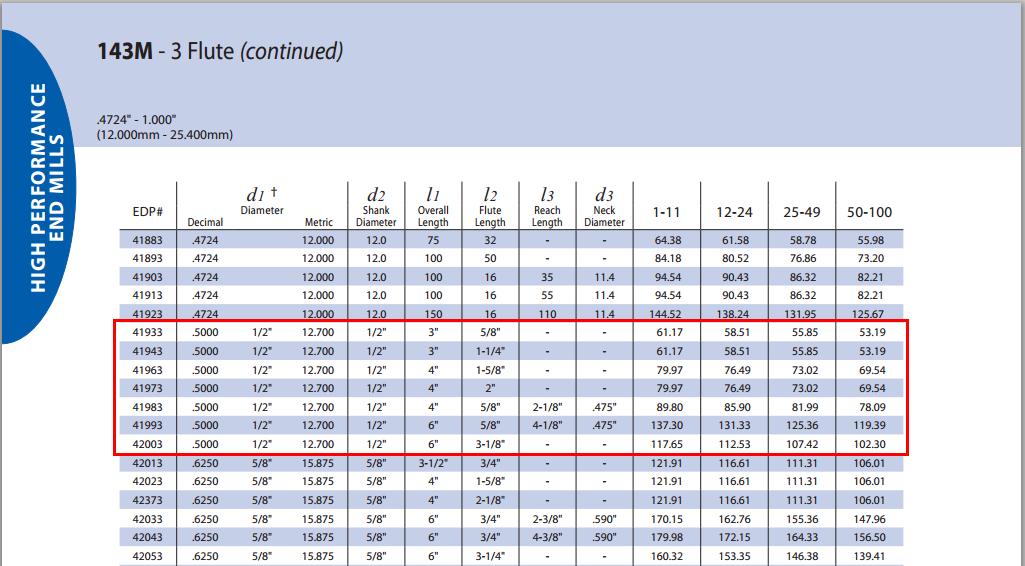

This is the normal end mill style.

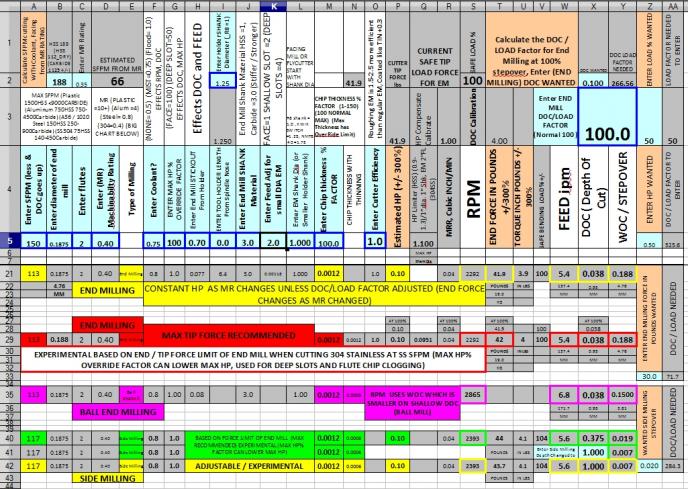

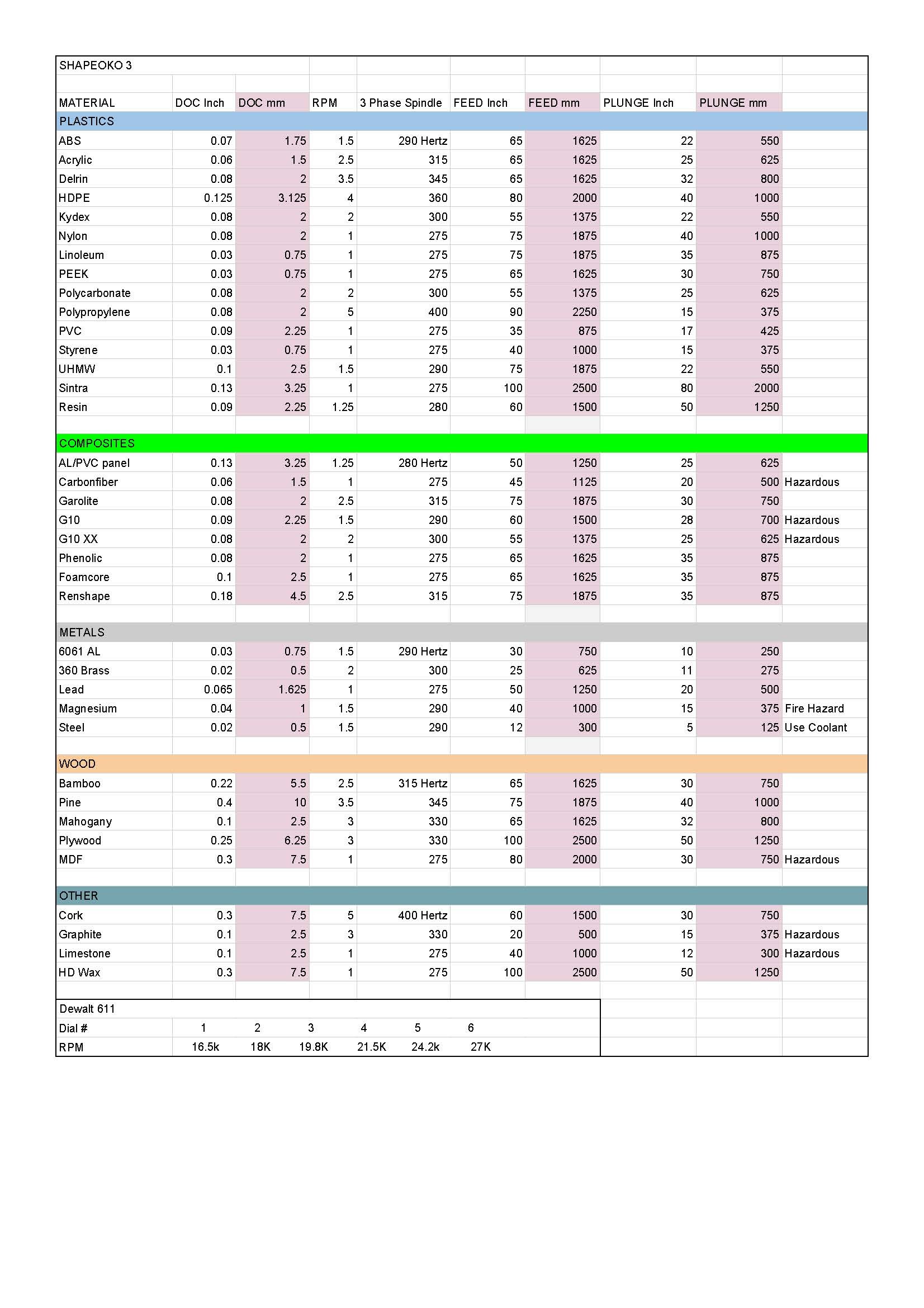

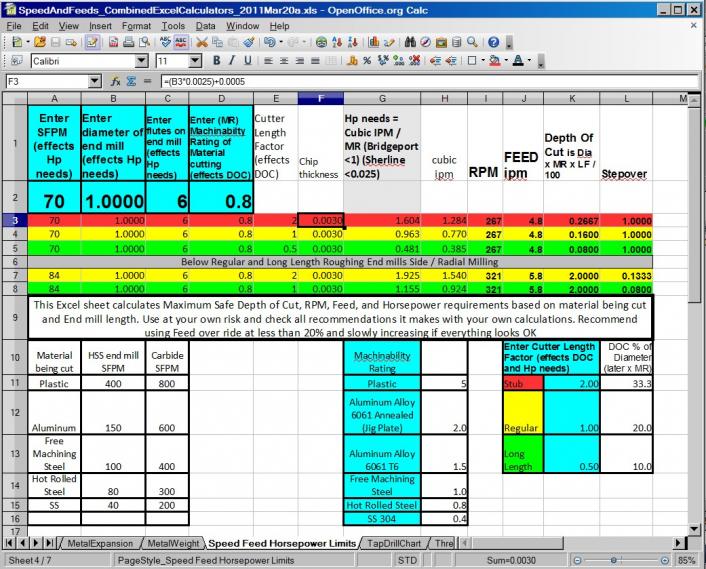

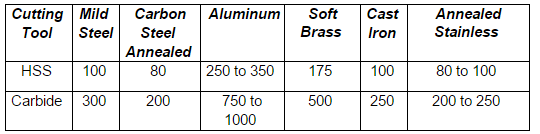

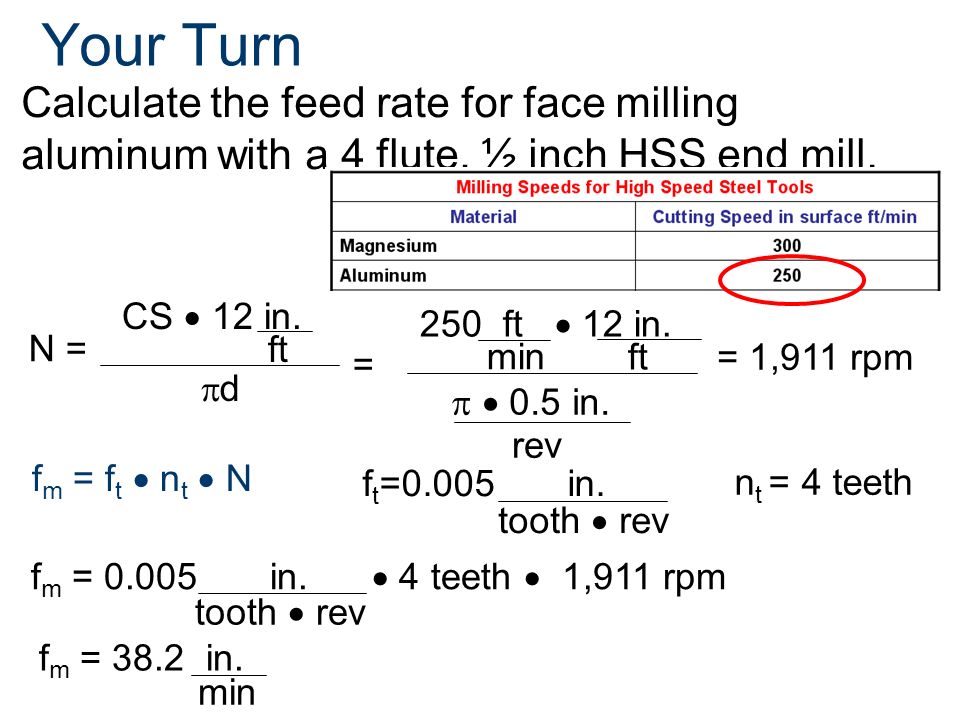

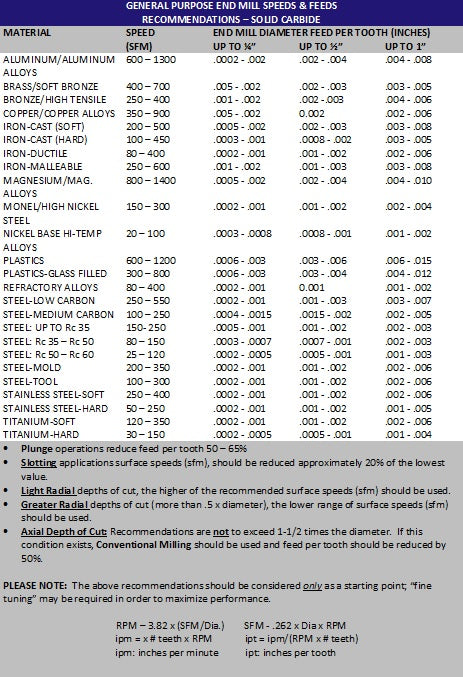

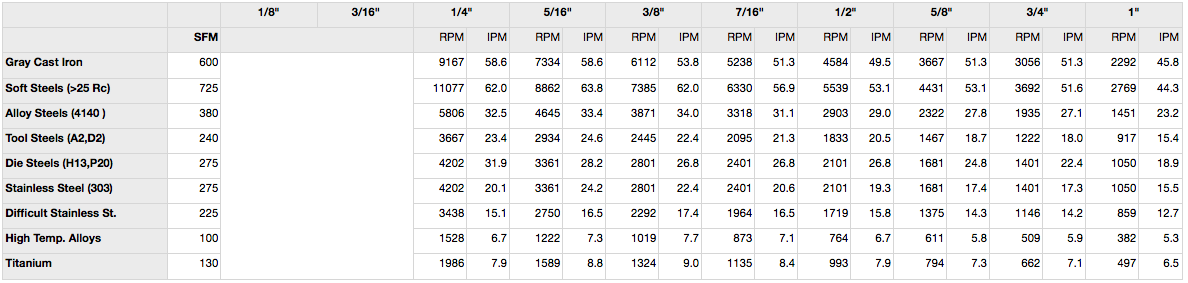

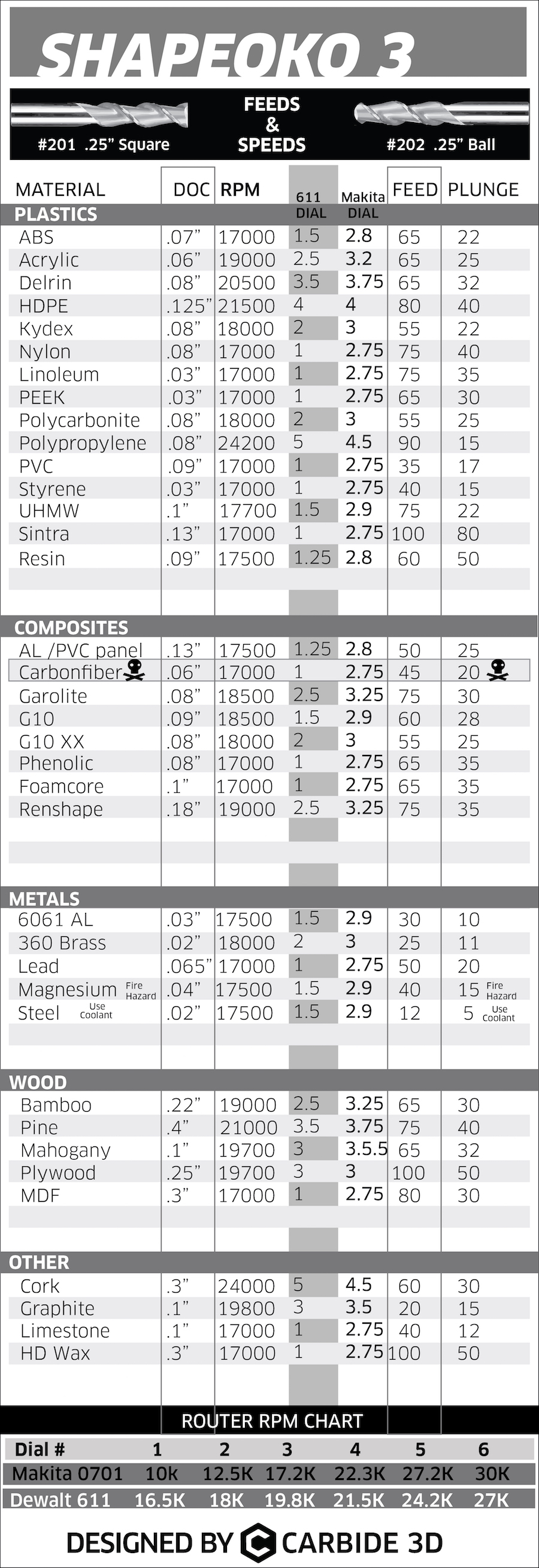

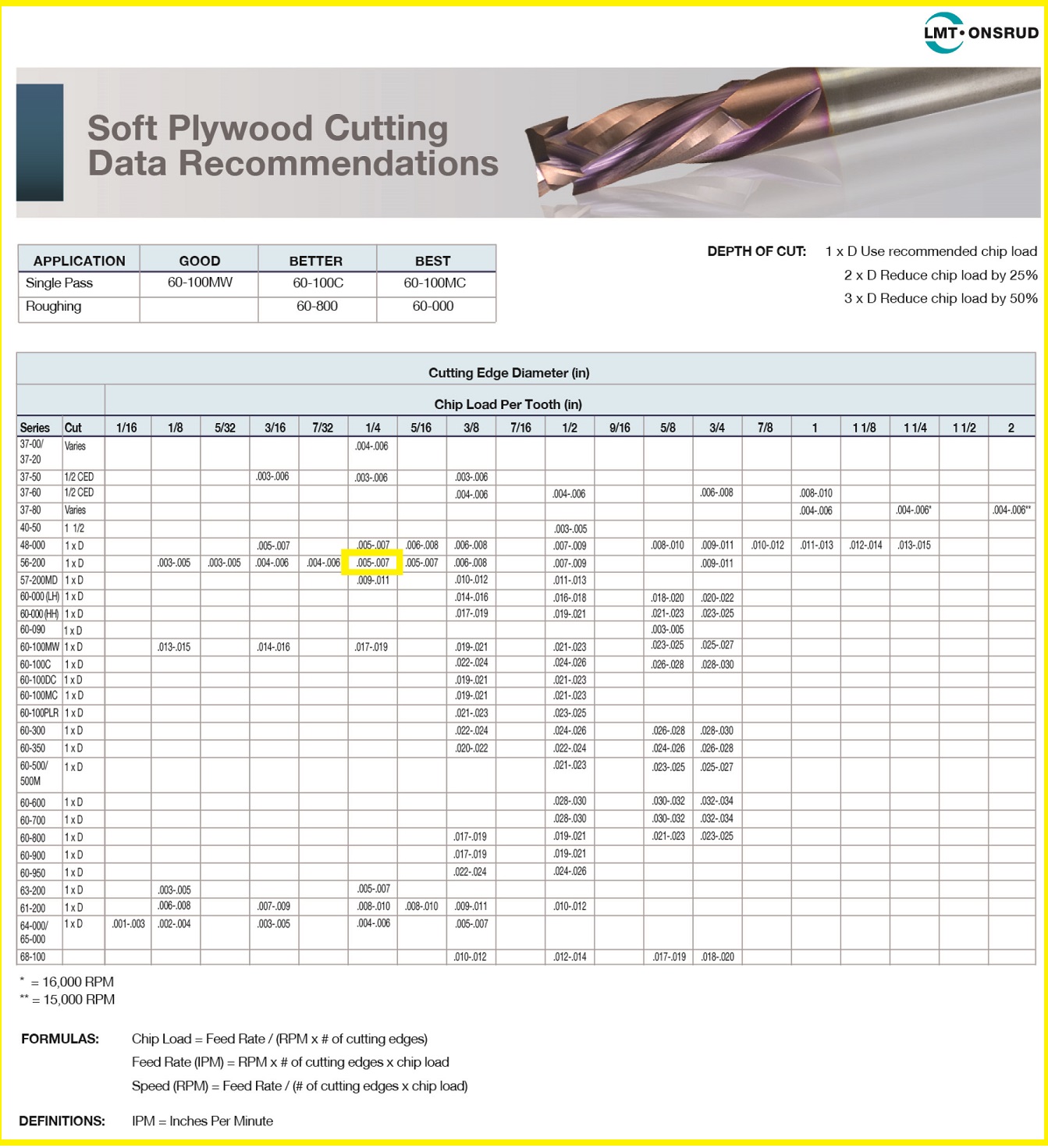

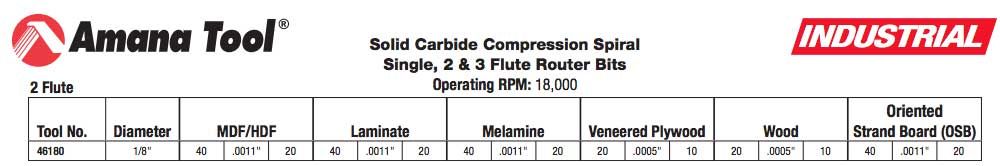

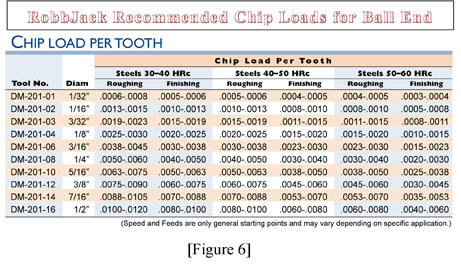

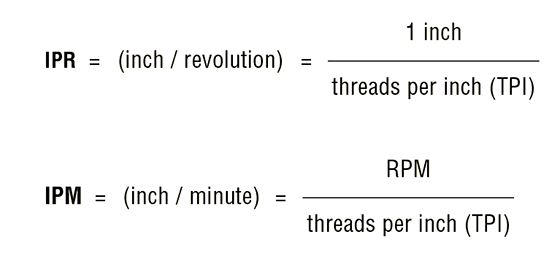

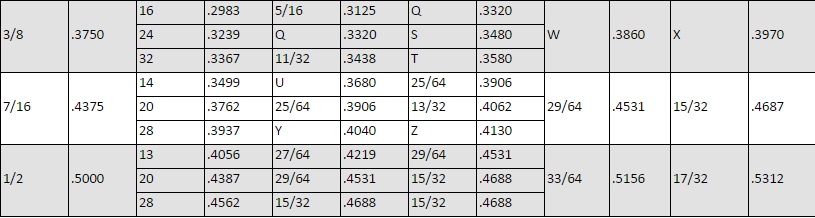

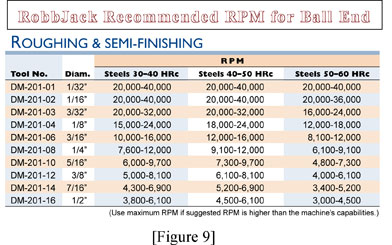

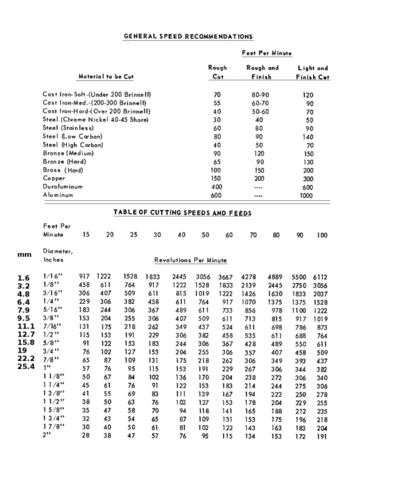

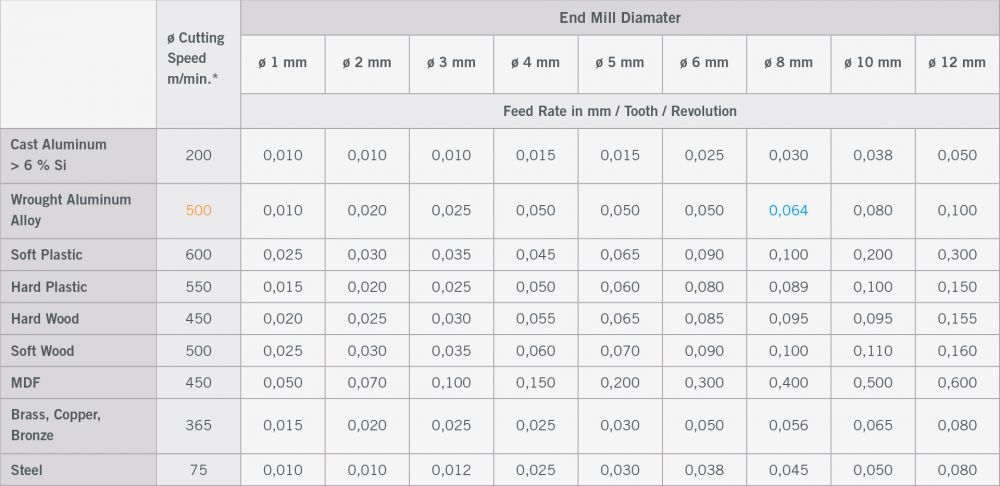

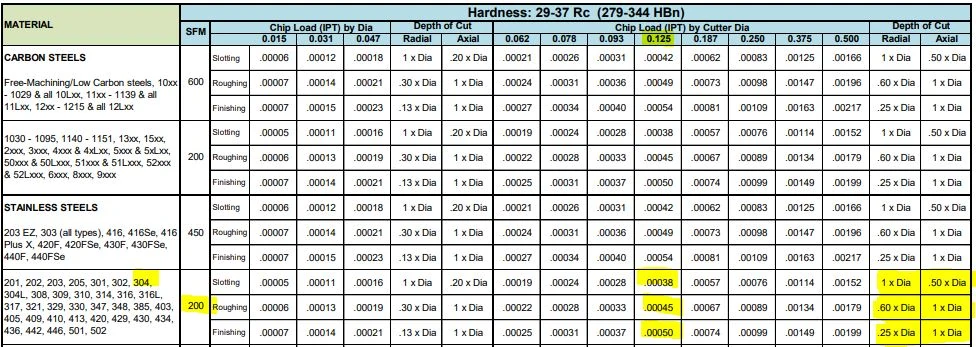

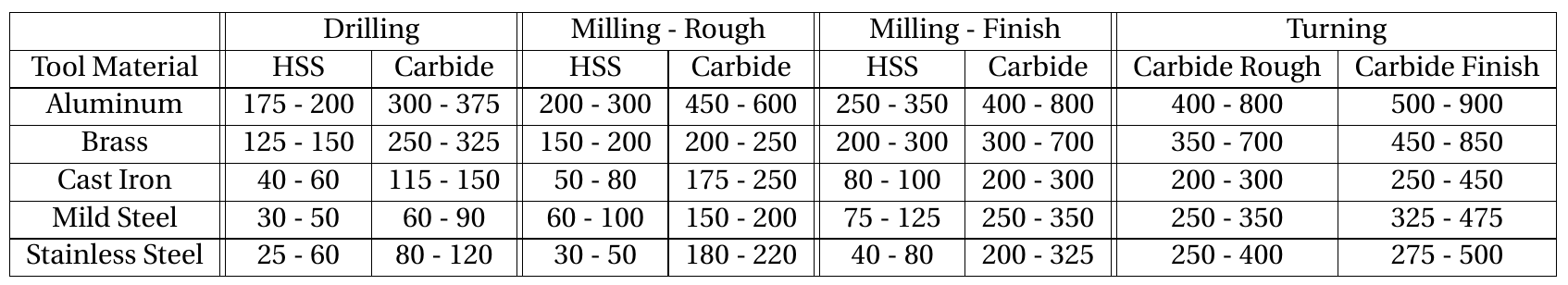

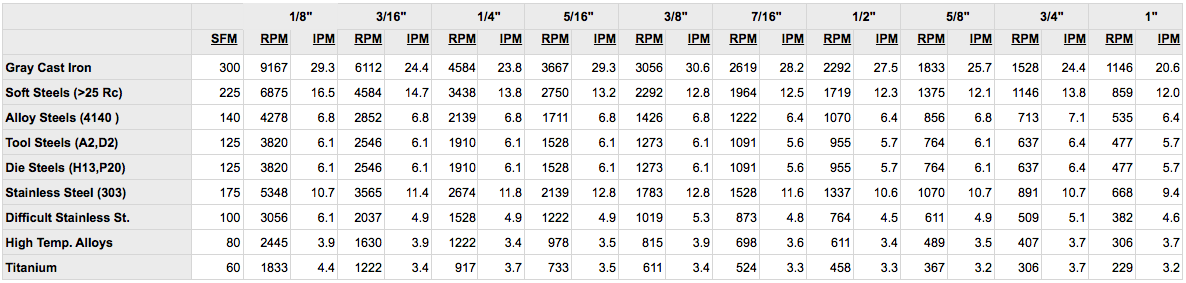

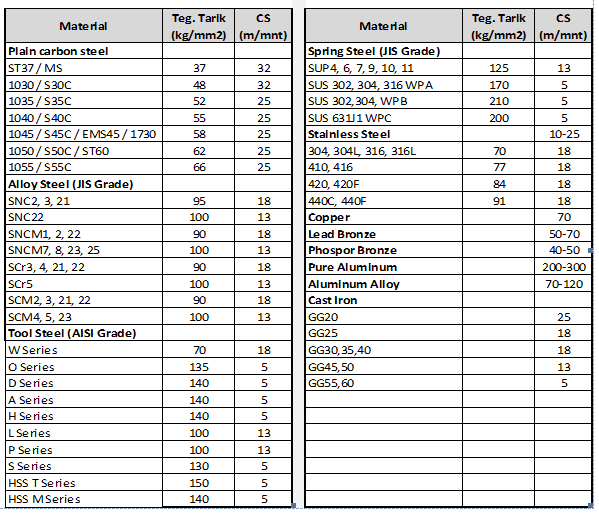

End mill rpm chart. Hit the calculate. Enter cutter diameter and surface speed to calculate the r p m. Feedrate in tooth cutting speed ft min end mill diameter in material 1 4 1 roughing finishing aluminum 0 003 0 009 600 800 bronze medium 0 003 0 007 250 300 bronze hard 0 002 0 005 125 150 cast iron soft 0 003 0 008 60 80 cast iron hard 0 002 0.

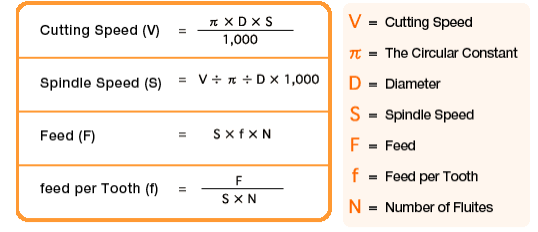

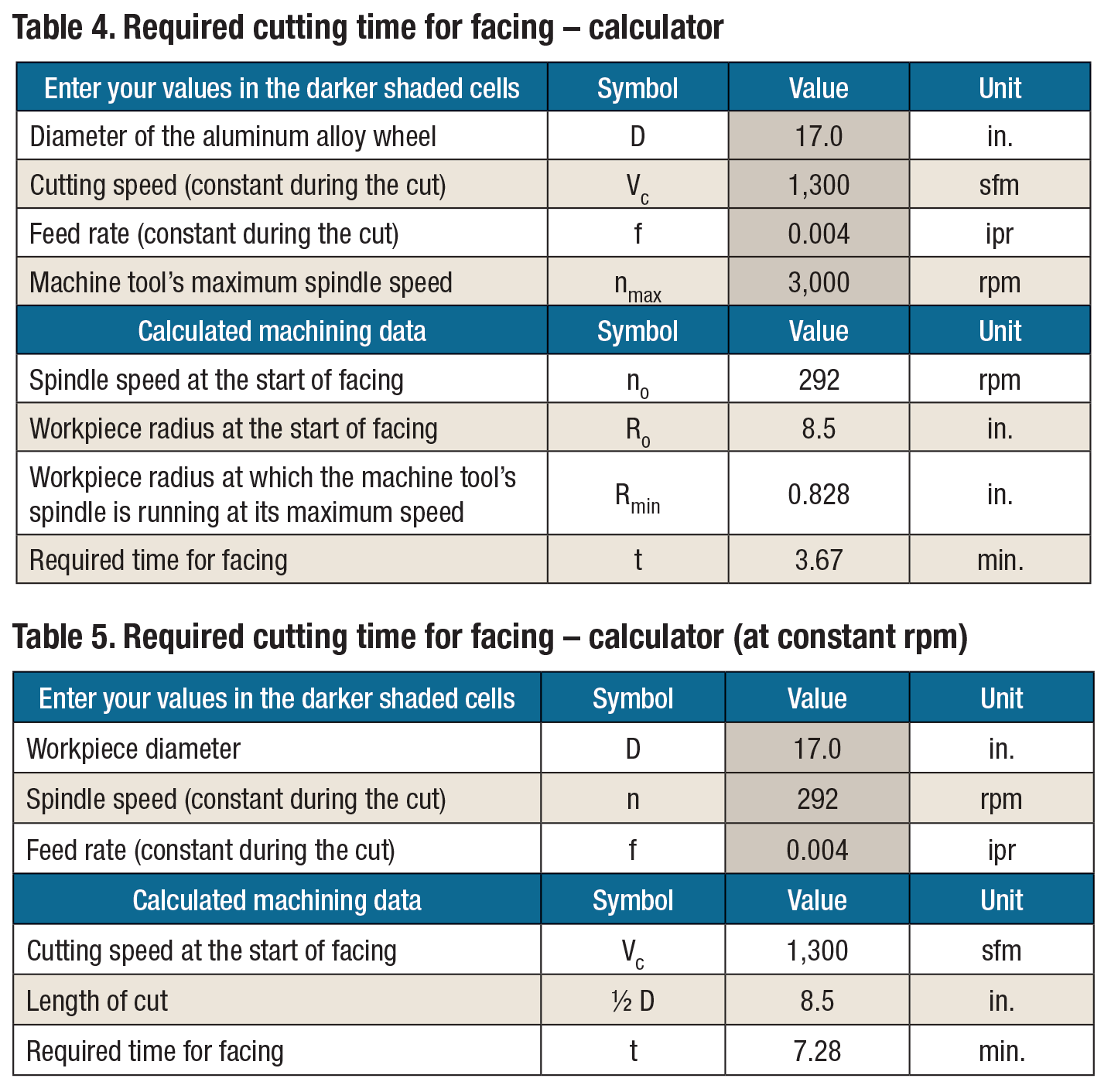

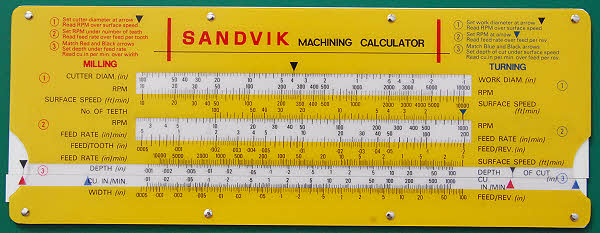

Milling drilling reaming top turning speeds are adjusted to the feed rate of the mini lathe 0 004 rev a depth of cut of 0 040 and a tool life of 180 minutes. 4 kane industrial drive hudson ma 01749 tel. With downcut geometry the spiral is reversed so it pushes down instead of.

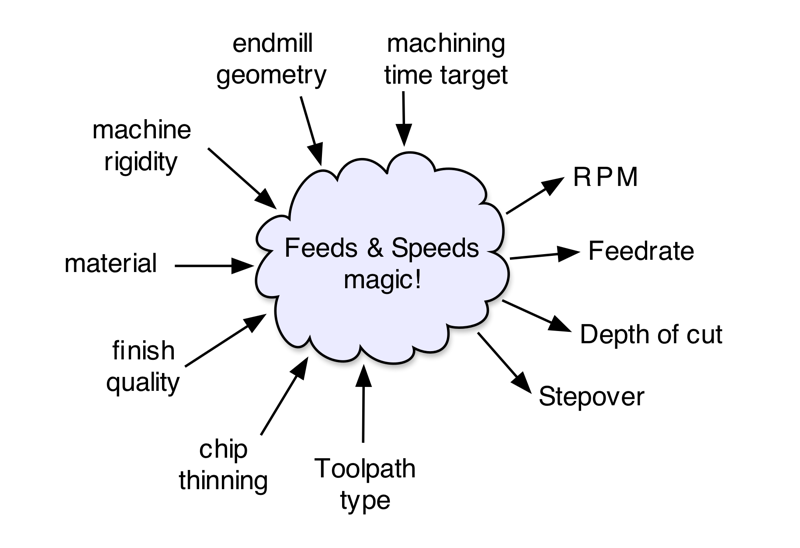

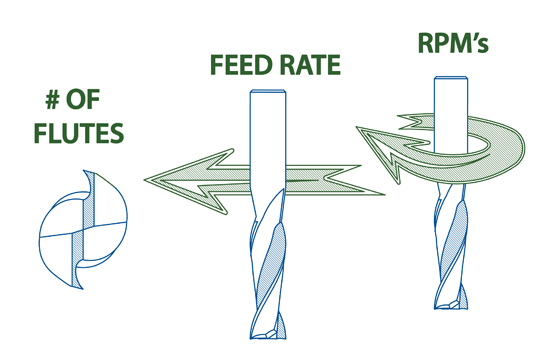

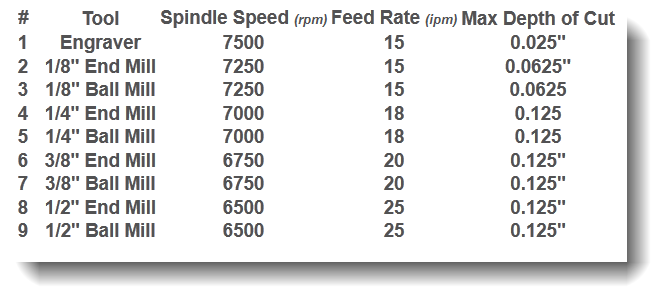

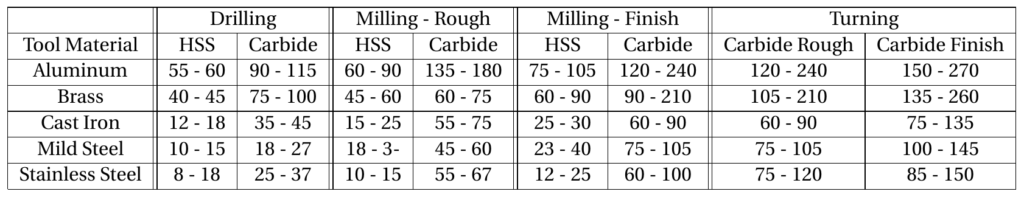

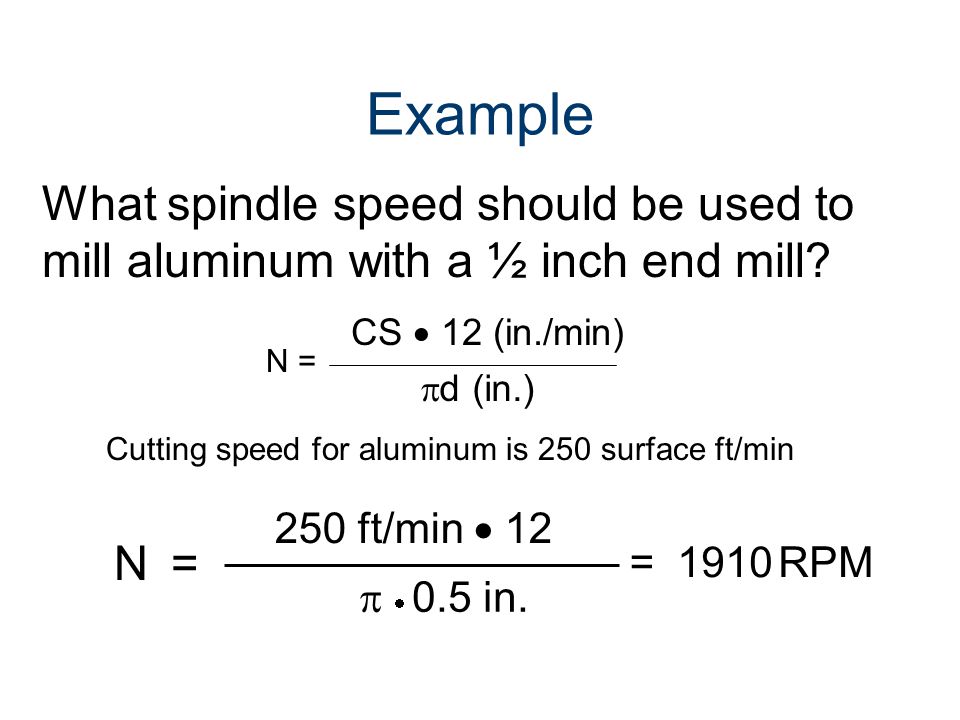

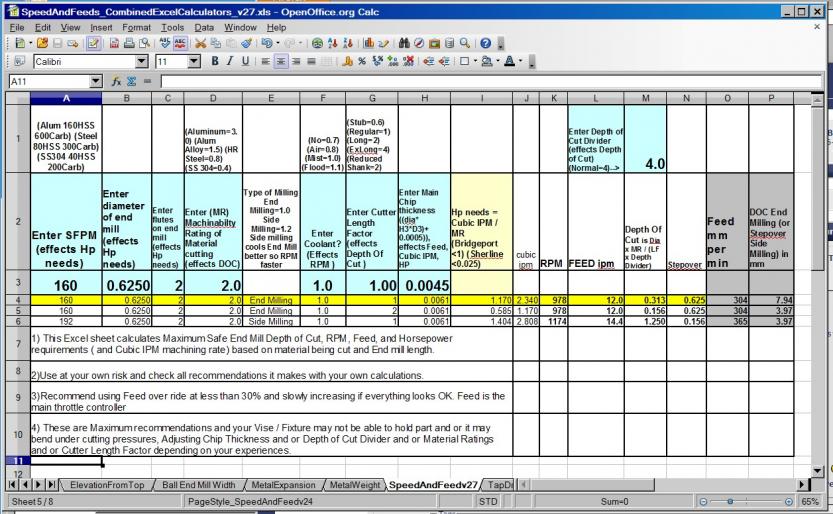

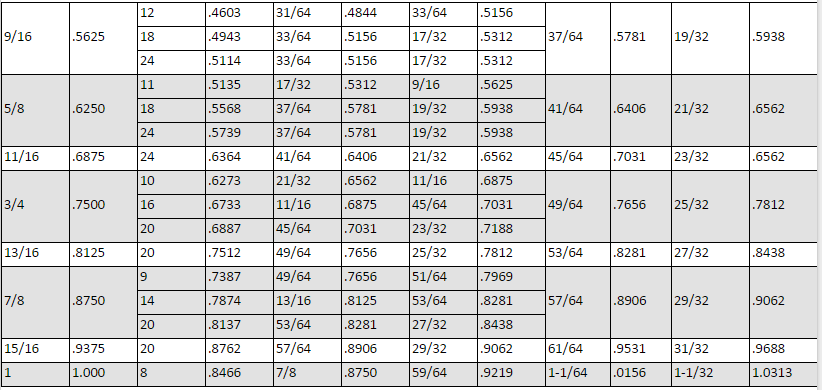

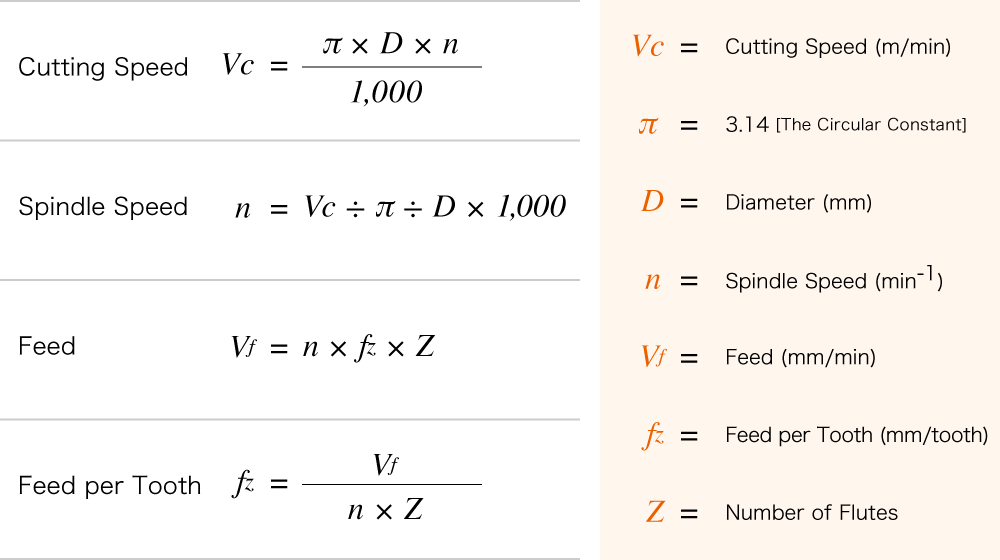

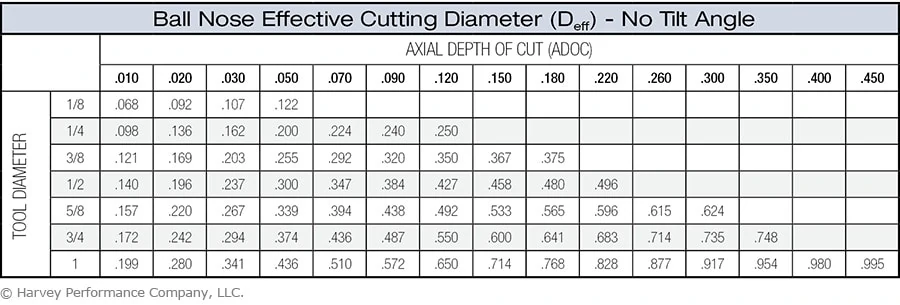

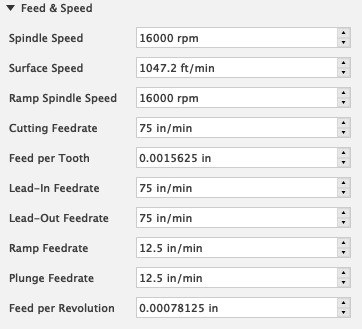

Choose a type of operation drilling reaming boring counterboring face milling slab milling side milling end milling or turning select your stock material choose a material for the tool high speed steel or carbide input the quantity of teeth for the tool and the diameter of the workpiece cutter. Multiply the listed speeds by a factor of 2 when using carbide tooling. Speed and feed calculators ball mill finish calculator part spacing calculator g and m code characters standard end mill sizes standard drill sizes drill and counterbore sizes.

Feeds and speeds for end milling using high speed steel tooling. For deep slots reduce the ft min. End mill and armor mill speed and feeds tables 2l speed and feed calculator for machining speeds.

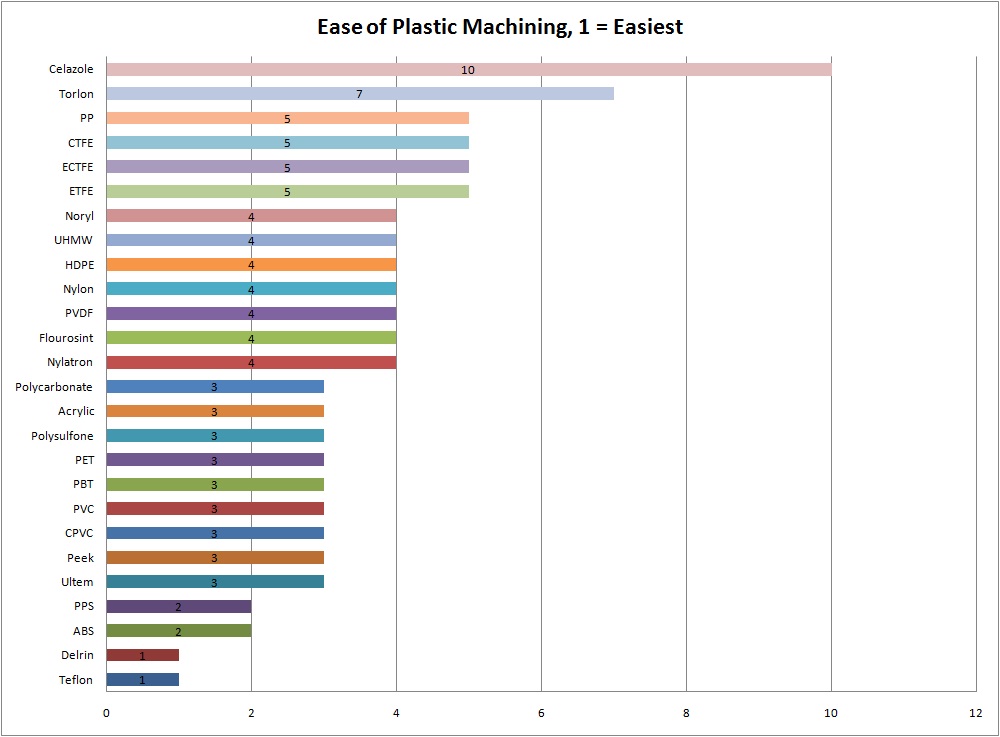

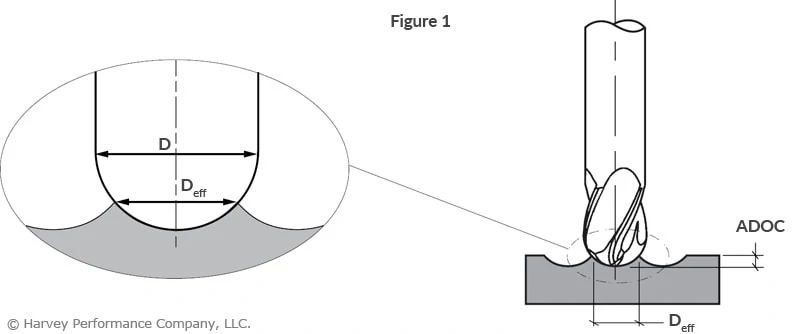

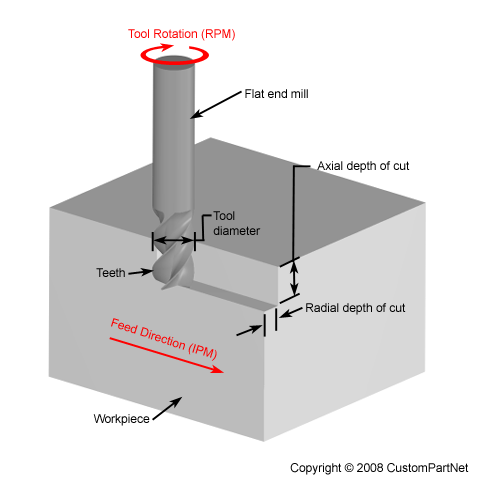

We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end mills. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill. This will adjust the feedrate if less than the tool rad.

These are probably the worst about splintering though with serious fine tuning and slower feeds and speeds you may be able to tame it a bit. By 20 to 40. Milling speeds and feeds charts.

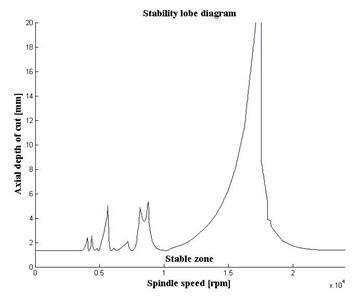

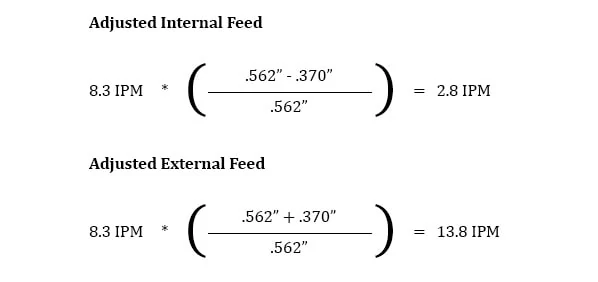

Engraving tools end mills cutters spring loaded engraving tools vacuum chucks pumps for workholding. Milling speed and feed calculator determine the spindle speed rpm and feed rate ipm for a milling operation as well as the cut time for a given cut length. Radial side depth of cut.

/WXL_Coating_End_Mill_Series_Vol.5-2_(N-79)-45.jpg)